1、 in the engineering design, the layout of cable trays should be based on economic rationality, technical feasibility, operational safety and other factors to determine the best program, but also to fully meet the requirements of construction and installation, maintenance and cable laying.

2、The height of the cable tray from the ground when laid horizontally is generally not less than 2.5m, and the part below 1.8m from the ground when laid vertically should be protected by metal cover, except when laid in the special electrical room. Cable bridges laid horizontally in the equipment mezzanine or on the human road and below 2.5m, should take protective grounding measures.

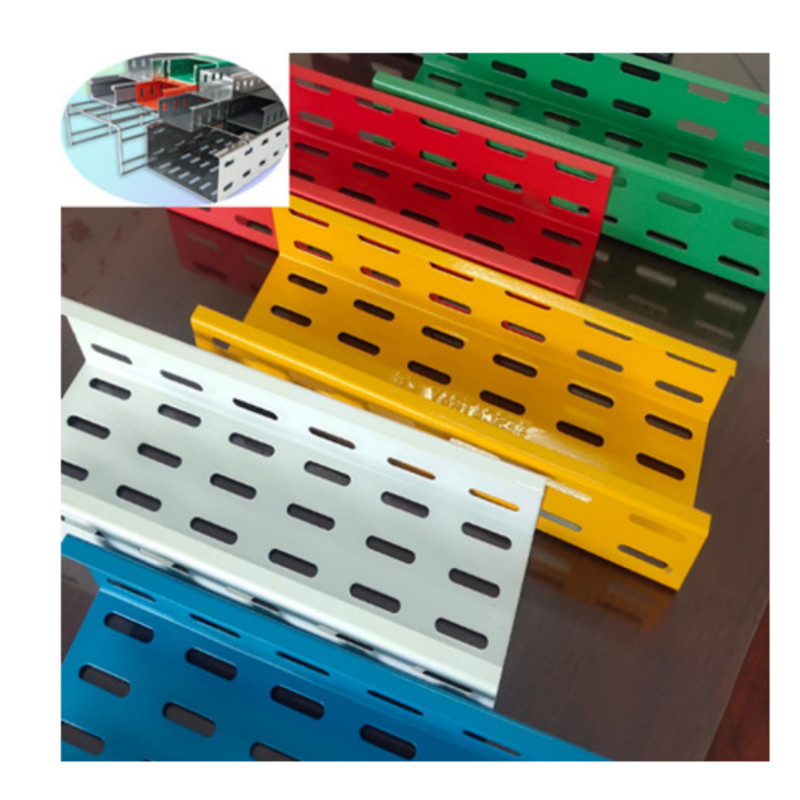

3、Cable containment, trunking and its support hangers used in corrosive environments, should be made of corrosion-resistant rigid materials. Or take anti-corrosion treatment, anti-corrosion treatment should meet the requirements of the engineering environment and durability. Corrosion resistance requirements are high or require clean places, it is appropriate to use aluminum cable tray.

4、Cable trough in the section of fire requirements, cable ladder tray, tray with fire-resistant or flame-retardant properties added to the board, network and other materials to form a closed or semi-closed structure, and take measures such as painting fireproof coating on the surface of the tray and its support hanger. Its overall fire resistance performance should meet the requirements of the relevant national norms or standards. In the engineering fire requirements of high places. Aluminum cable bridges are not suitable.

5、Cable lines that need to be shielded from electromagnetic interference. Or have protection from external shadows such as outdoor sunlight, oil, corrosive liquids, flammable dust and other environmental requirements. Should use non-porous tray cable tray.

6、In places where dust tends to accumulate, steel cable tray should be selected with a cover; in public passages or outdoor cross-road sections. The bottom cable tray should be padded or use non-porous tray.

7、Cables of different voltages and different purposes should not be laid in the same layer of cable tray: (1) cables above 1kV and 1kV and below: (2) double-circuit cables supplying the same path to the primary load; (3) cables for emergency lighting and other lighting: (4) power, control and telecommunication cables. If different levels of cables are laid in the same cable tray, additional partitions should be added in between to isolate them.

8、When the length of the straight section of the steel cable tray exceeds 30m, the aluminum cable tray exceeds 15m. Or when the cable tray through the building expansion (settlement) joints should be left with O-30mm compensation margin. Its connection should be used to expand the connection plate.

9、Cable ladder rack, tray width and height of the choice should be in line with the filling rate requirements, cable in the ladder rack, tray filling rate in general, power cable can be 40% -50%, control cable can be 50%. 70%. And it is appropriate to set aside l0% a 252 project development margin.

10、When choosing the load level of the cable tray, the working average load of the cable tray should not be greater than the rated average load of the selected load level of the cable tray, if the actual span of the support hanger of the cable tray is not equal to 2m. Then the working uniform load should meet: where qG—- working uniform load, kN / m; qE—- rated uniform load, kN / m; LG—- actual span, m.

Post time: May-15-2023