1、Different applications

Trough cable tray: suitable for laying computer cables, communication cables, thermocouple cables and other highly sensitive system of control cables, etc.

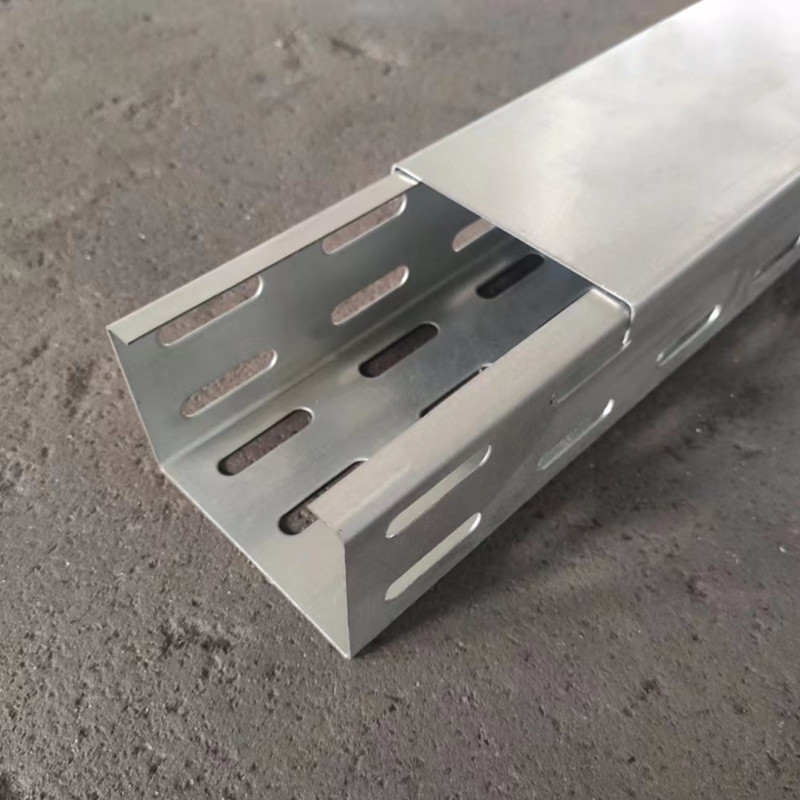

Perforated cable tray: is the most widely used in petroleum, chemical, light industry, television, telecommunications, etc.

2、Different advantages

Cable trough: it has a better effect on control cable shielding interference and protection of cables in heavy corrosive environments.

Ventilated cable tray: it has the advantages of light weight, large load, beautiful shape, simple structure, easy installation, etc.. It is suitable for both the installation of power cables, but also for the laying of control cables

3、Different varieties to choose

(1) need to shield the cable network of electrical interference or have protection from external (such as: corrosive liquid rest, flammable dust and other environments) impact requirements, should be selected trough composite anti-corrosion shielded cable trays (with cover).

(2) strong corrosive environment should be used (F) class composite epoxy resin anti-corrosion flame retardant cable tray. Bracket arm, strut channel, bracket should also use the same material to improve the service life of the cable tray and accessories, cable channels in the easy to accumulate dust and other need to cover the environment or outdoor places should add a cover plate.

(3) In addition to the above, according to the site also environment and technical requirements to choose perforated type, trough type, ladder type, glass anti-corrosion flame retardant cable trays or steel ordinary type cable tray. In the easy to accumulate dust and other need to cover the environment or outdoor places should be added cover.

(4) In the public channel or outdoor crossing road section, the bottom of the bottom ladder should be added to the pad or use the pallet in the section. When crossing the public channel with large span, the load capacity of the bridge can be increased or the line frame can be selected according to the user’s requirements.

(1) cable containment, trunks and their support hangers used in a corrosive environment, should be manufactured using corrosion-resistant rigid materials, or take anti-corrosion treatment, anti-corrosion treatment should meet the requirements of the engineering environment and durability.

(2) cable trays in the fire requirements of the section, can be added in the cable ladder frame, tray with fire-resistant or flame-retardant properties of the plate, network and other materials to form a closed or semi-closed structure, and take measures such as painting fireproof coating on the surface of the bridge and its support hanger, its overall fire resistance should meet the requirements of the relevant national norms or standards.

(3) in the project fire requirements of high places, should not use aluminum cable trays.

(4) cable ladder tray, tray width and height should be selected to meet the requirements of the filling rate, cable ladder frame and tray filling rate in general, power cables can be 40% to 50%, control cables can be 50% to 70%, and it is appropriate to set aside 10% to 25% of the project development margin.

Post time: Jan-04-2023