Factory Outlets Fiber Cable Tray - HC1-E Hesheng Perforated Elbow 90° – Hesheng

Factory Outlets Fiber Cable Tray - HC1-E Hesheng Perforated Elbow 90° – Hesheng Detail:

Product description

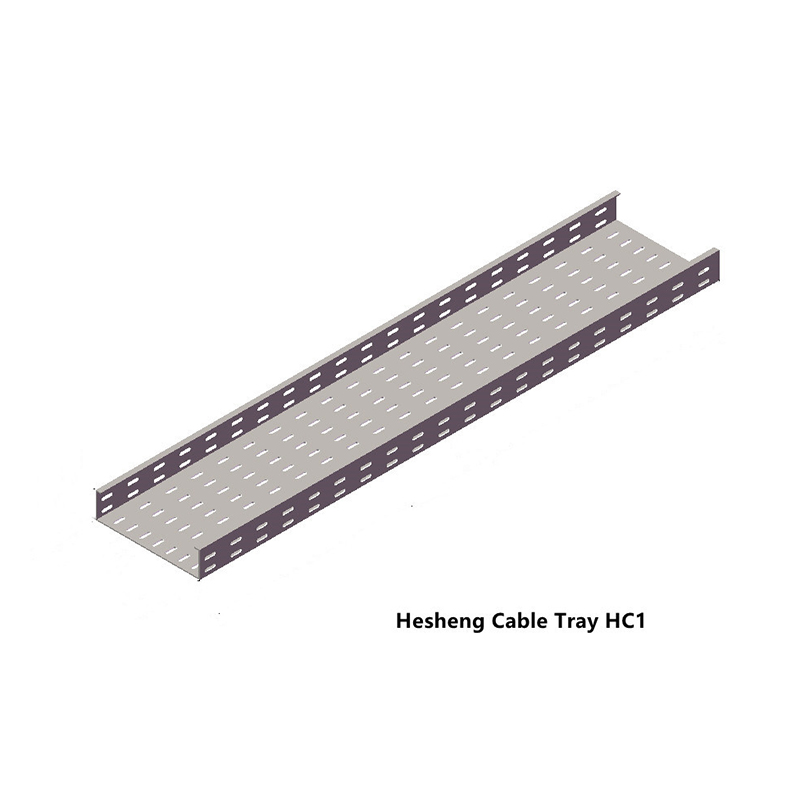

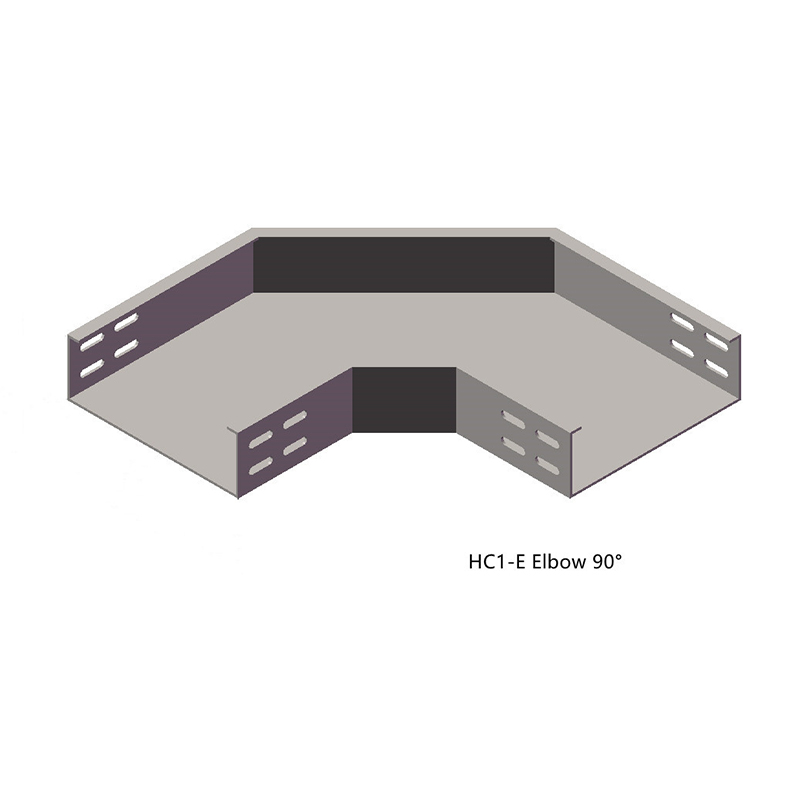

Elbow 90°for Perforated Cable Tray HC1

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

perforated cable tray allows for hold down or cable attachment, and heat dissipation.

The continuous perforated cable tray allows for constant cable support. Our products consist of Wire Mesh Cable Tray, Cable Tray with holes , solid pan bottom cable tray, Cable Trunking, Cable Ladder, Wireway, Strut Channel and accessories, which can be widely used in construction, energy, electricity and plant. We passed the ISO 9001 quality management system certification, UL Certificate (U.S.A.), and CE Certificate (E.U.)

Every straight piece of our perforated cable tray has an average length of 3000 mm, other length available against the requirements of the customers.

Moreover,H.S. also develop various accessories for our range which are used for support & installation of cables over the cable trays.

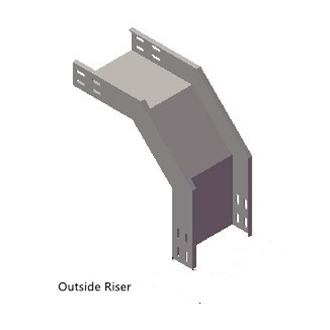

H.S.offer a wide range of compents of perforated cable trays. 90°Elbow is one of the components used as the connector in the place of 90°corner.

These perforated cable trays are offered in different materials , generally fabricated in mild steel.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

Product Specifications

|

Oerdering Code |

W(mm) |

H(mm) |

|

|

HC1-E3 |

HC1-E3-50-50 |

50 |

50 |

|

HC1-E3-100-50 |

100 |

50 |

|

|

HC1-E3-150-50 |

150 |

50 |

|

|

HC1-E3-200-50 |

200 |

50 |

|

|

HC1-E3-250-50 |

250 |

50 |

|

|

HC1-E3-300-50 |

300 |

50 |

|

|

HC1-E3-400-50 |

400 |

50 |

|

|

HC1-E3-450-50 |

450 |

50 |

|

|

HC1-E3-500-50 |

500 |

50 |

|

|

HC1-E3-600-50 |

600 |

50 |

|

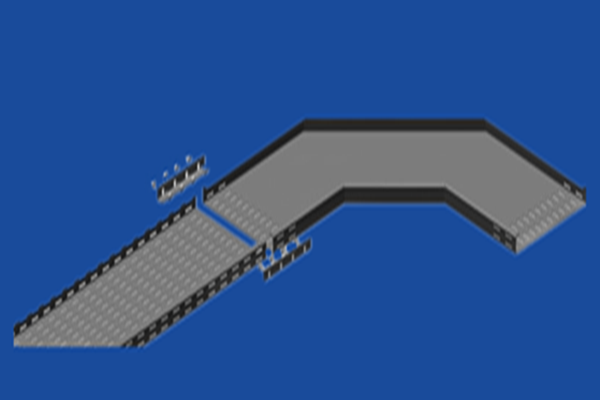

Installation Guide

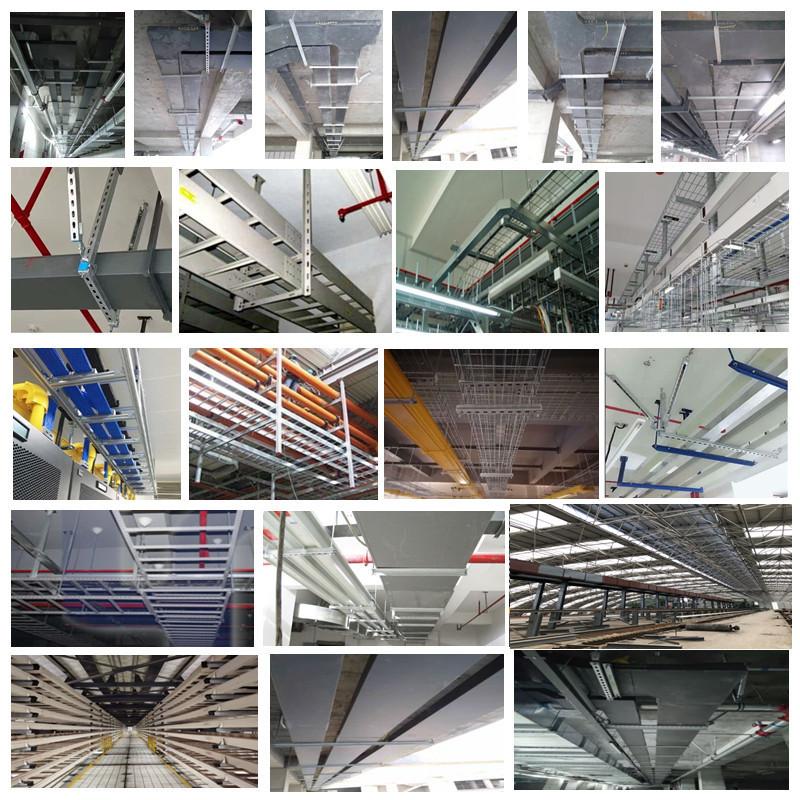

Installation case on site for perforated cable tray HC1

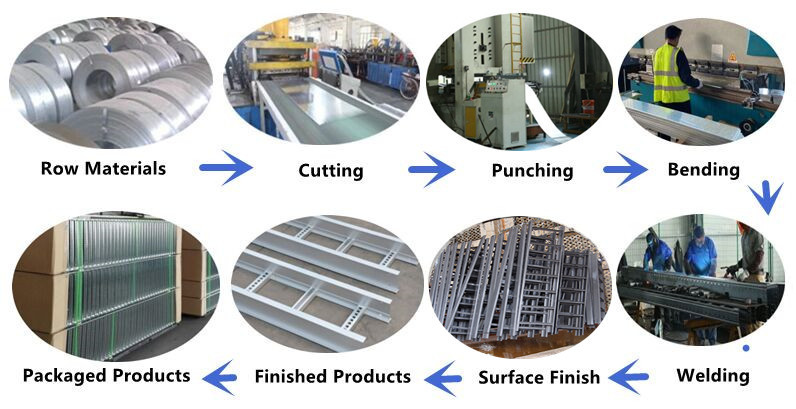

Production Process

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing and Delivery for Cable tray

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

Installation case on site for Hesheng cable support system

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

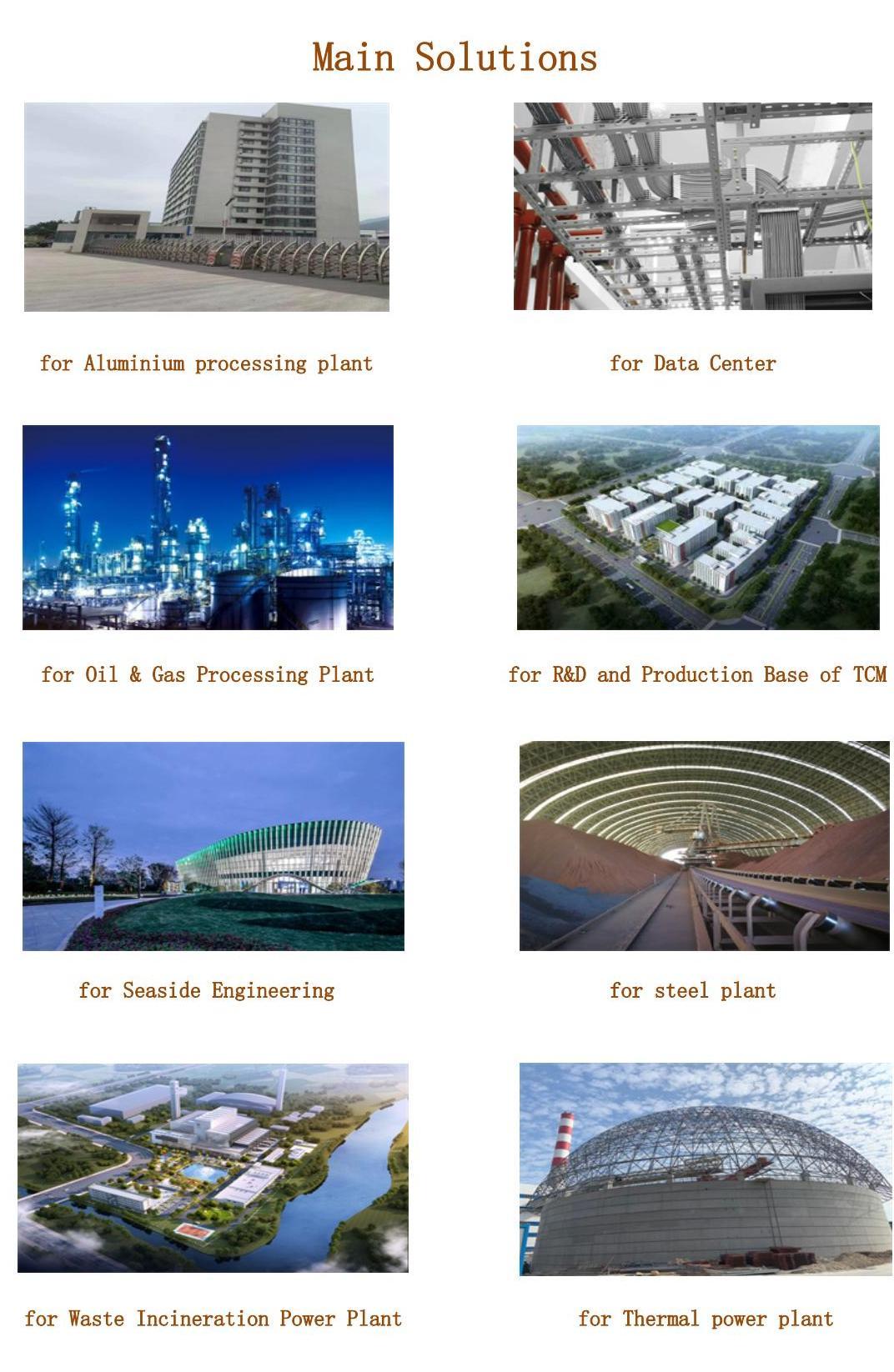

Product application program

Actual Test on Site

Certificate

Product detail pictures:

Related Product Guide:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Factory Outlets Fiber Cable Tray - HC1-E Hesheng Perforated Elbow 90° – Hesheng , The product will supply to all over the world, such as: Lisbon, Johannesburg, Armenia, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!