Low MOQ for Cable Tray Support Systems - HC1-C Hesheng Perforated Cable Tray – Hesheng

Low MOQ for Cable Tray Support Systems - HC1-C Hesheng Perforated Cable Tray – Hesheng Detail:

Product description

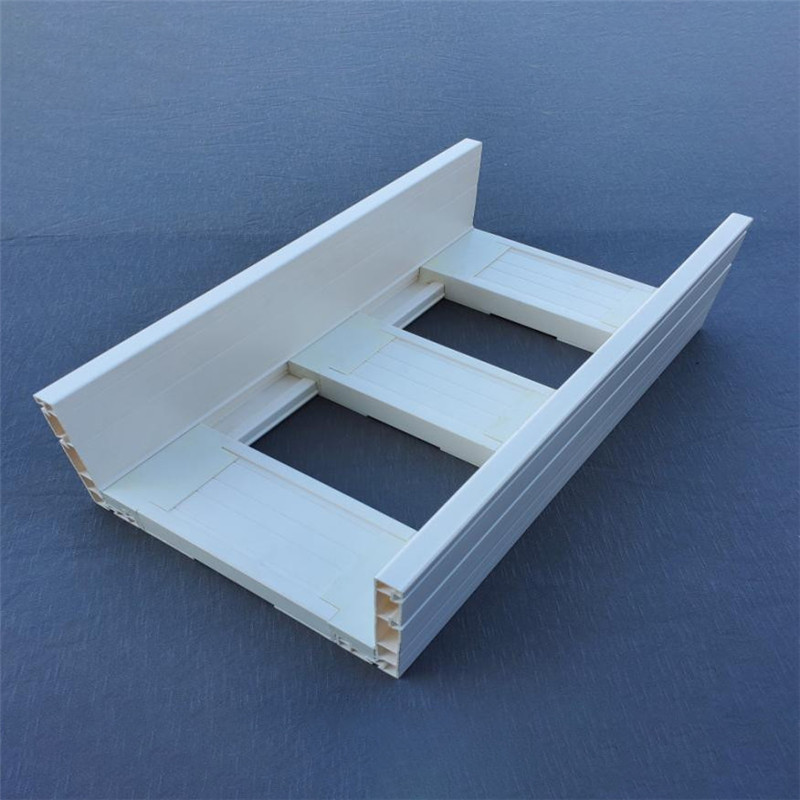

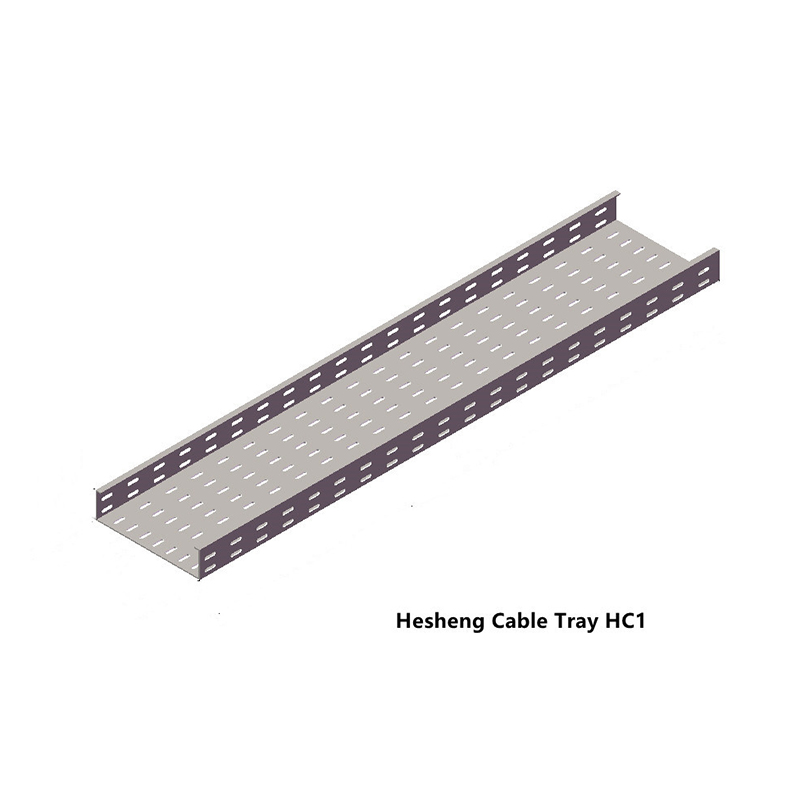

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

Channel Cable Trays consist of a one-piece, ventilated or solid bottom contained within longitudinal side members. Provides ventilation with added cable support frequency and with the bottom configuration providing cable support every 4 or less inches. Available in metal and nonmetallic materials. Generally used with control and instrumentation cables in moderate heat generating applications with short to intermediate support spans of 5 feet to 20 feet. Trough cable tray bottom is available in flat sheet or corrugation that is 3 times stronger and 21 times stiffer than flat sheet bottoms. Corrugated seams between jointing sections eliminate the need for bottom seam splices. Load Depths: 3″ through 9″.Channel Cable Tray is available in the following material types: mill steel, carbon steel, pre-galvanized steel, steel HDG, and stainless steel, aluminum, polymer alloy, plastic, FRP or GRP.

perforated cable tray allows for hold down or cable attachment, and heat dissipation.

The continuous perforated cable tray allows for constant cable support. Our products consist of Wire Mesh Cable Tray, Cable Tray with holes , solid pan bottom cable tray, Cable Trunking, Cable Ladder, Wireway, Strut Channel and accessories, which can be widely used in construction, energy, electricity and plant. We passed the ISO 9001 quality management system certification, UL Certificate (U.S.A.), and CE Certificate (E.U.)

Every straight piece of our perforated cable tray has an average length of 3000 mm, other length available against the requirements of the customers.

Moreover,H.S. also develop various accessories for our range which are used for support & installation of cables over the cable trays.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

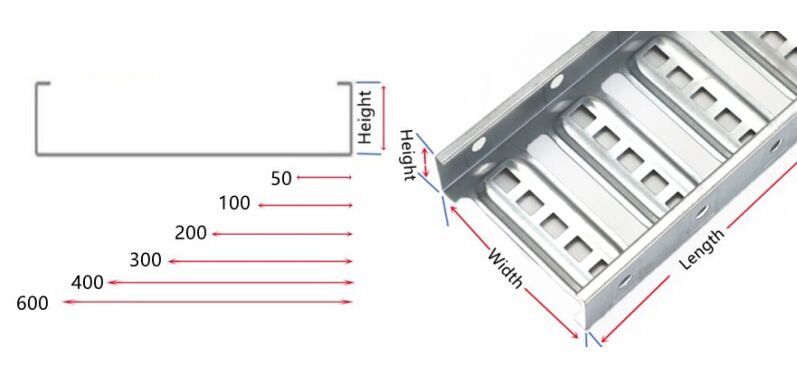

Metal Perforated Cable Tray HC1 Specification

|

Oerdering Code |

W |

H |

L |

|

|

HC1 |

HC1-50-50 |

50 |

50 |

3000 |

|

HC1-100-50 |

100 |

50 |

3000 |

|

|

HC1-150-50 |

150 |

50 |

3000 |

|

|

HC1-200-50 |

200 |

50 |

3000 |

|

|

HC1-250-50 |

250 |

50 |

3000 |

|

|

HC1-300-50 |

300 |

50 |

3000 |

|

|

HC1-400-50 |

400 |

50 |

3000 |

|

|

HC1-450-50 |

450 |

50 |

3000 |

|

|

HC1-500-50 |

500 |

50 |

3000 |

|

|

HC1-600-50 |

600 |

50 |

3000 |

|

|

HC1-75-75 |

75 |

75 |

3000 |

|

|

HC1-100-75 |

100 |

75 |

3000 |

|

|

HC1-150-75 |

150 |

75 |

3000 |

|

|

HC1-200-75 |

200 |

75 |

3000 |

|

|

HC1-250-75 |

250 |

75 |

3000 |

|

|

HC1-300-75 |

300 |

75 |

3000 |

|

|

HC1-400-75 |

400 |

75 |

3000 |

|

|

HC1-450-75 |

450 |

75 |

3000 |

|

|

HC1-500-75 |

500 |

75 |

3000 |

|

|

HC1-600-75 |

600 |

75 |

3000 |

|

|

HC1-100-100 |

100 |

100 |

3000 |

|

|

HC1-150-100 |

150 |

100 |

3000 |

|

|

HC1-200-100 |

200 |

100 |

3000 |

|

|

HC1-250-100 |

250 |

100 |

3000 |

|

|

HC1-300-100 |

300 |

100 |

3000 |

|

|

HC1-400-100 |

400 |

100 |

3000 |

|

|

HC1-450-100 |

450 |

100 |

3000 |

|

|

HC1-500-100 |

500 |

100 |

3000 |

|

|

HC1-600-100 |

600 |

100 |

3000 |

|

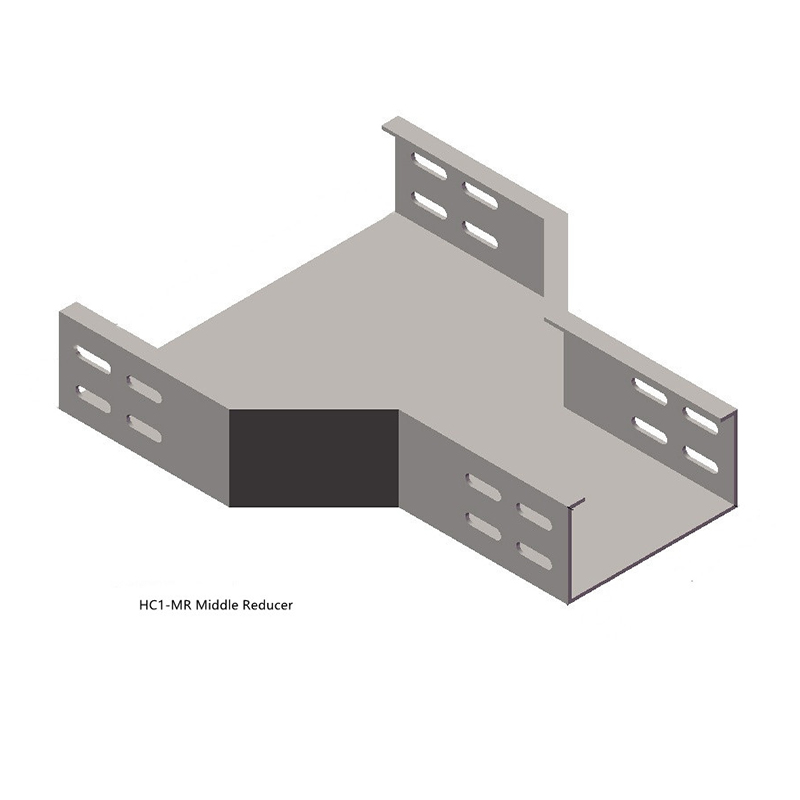

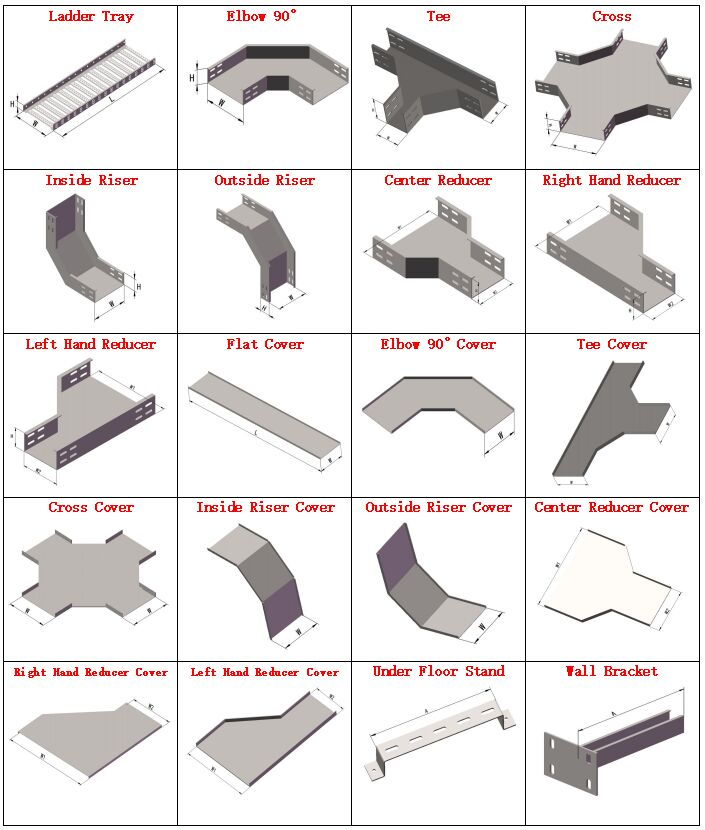

Bending components and Brackets

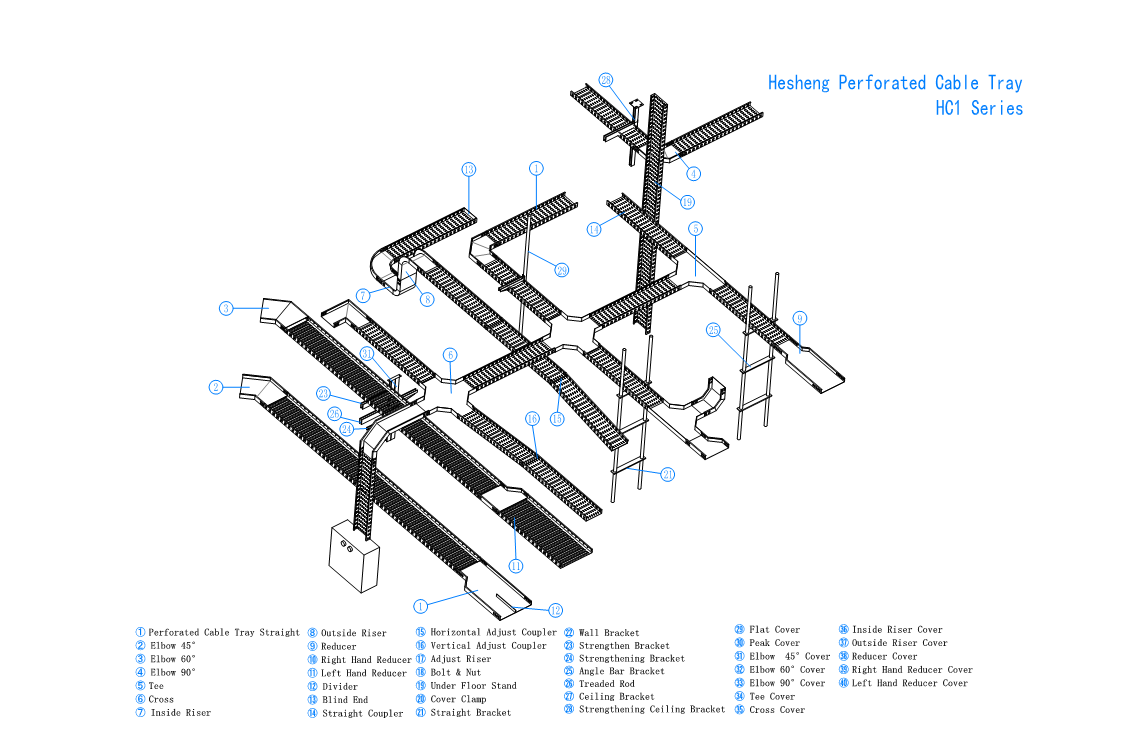

Schematic diagram of the Cable Tray space layout

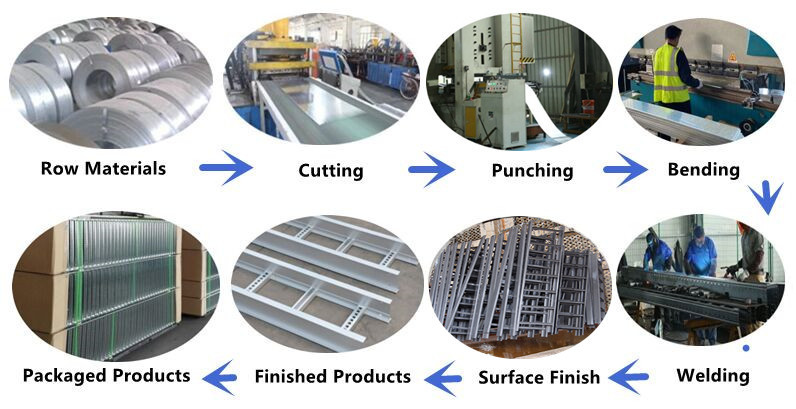

Production Process

production line for Metal Cable Tray Here is production line of cable tray and welcome to visit our factory

Packing and Delivery for Cable tray

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

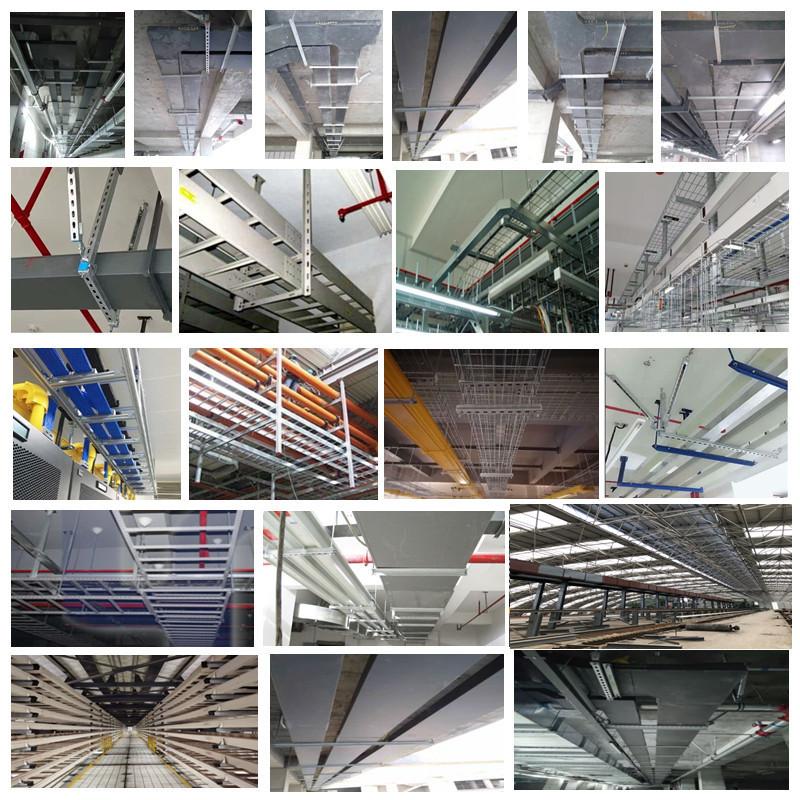

Installation case on site for Hesheng cable support system

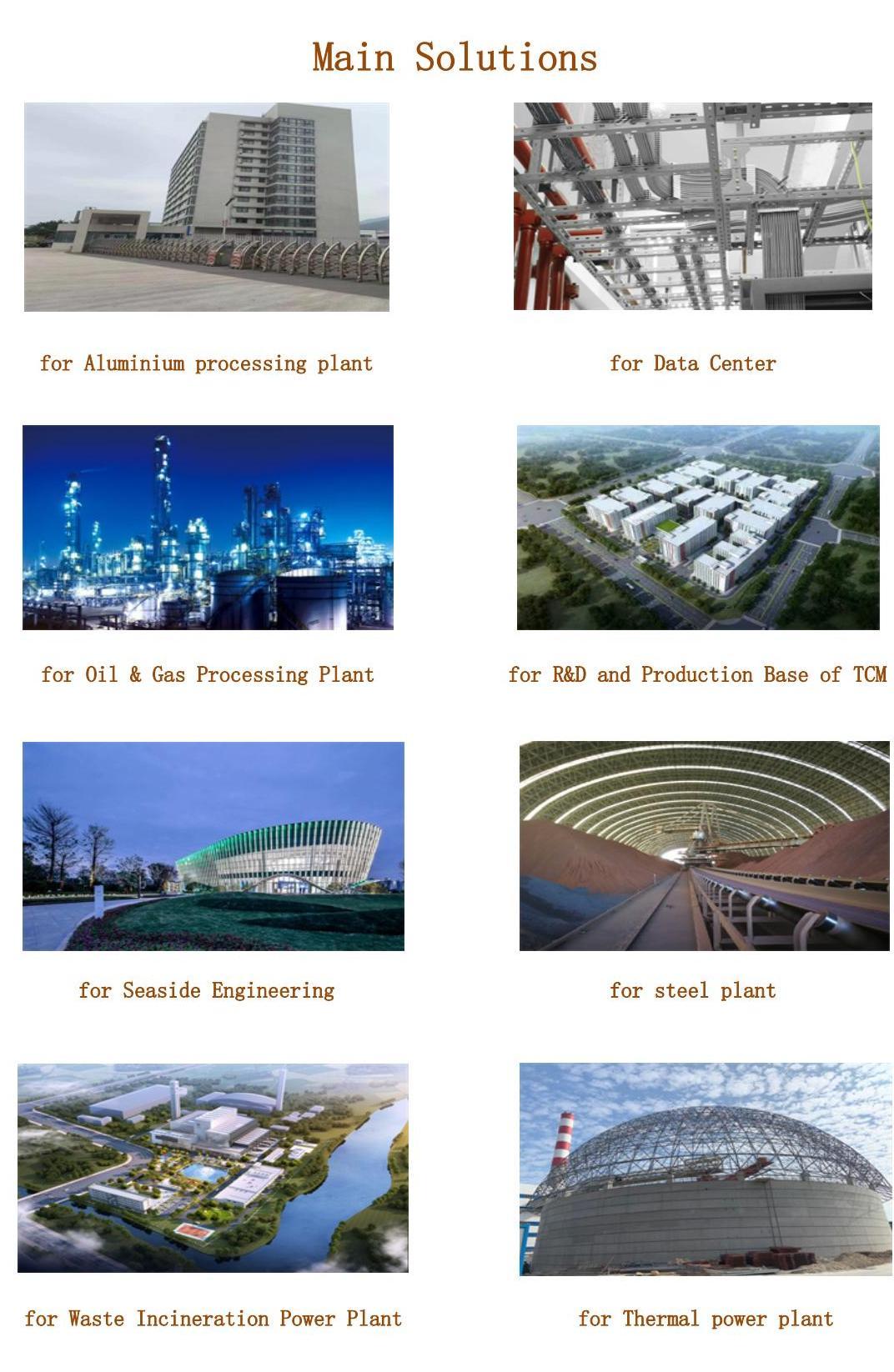

Product application program

Actual Test on Site

Installation case on site for perforated cable tray HC1

Certificate

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for Low MOQ for Cable Tray Support Systems - HC1-C Hesheng Perforated Cable Tray – Hesheng , The product will supply to all over the world, such as: Cape Town, Lithuania, Bahrain, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!