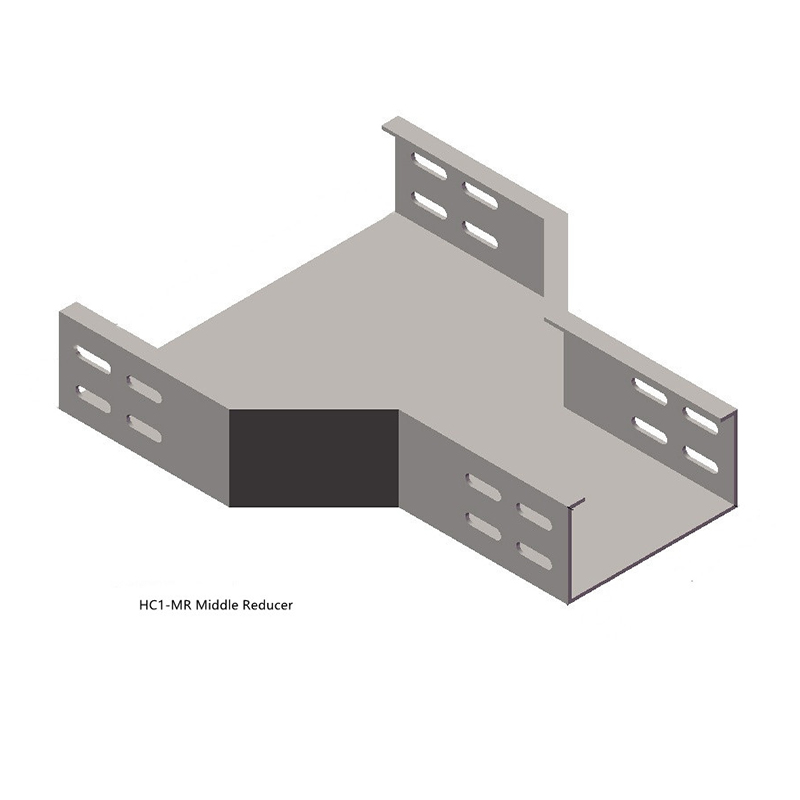

Manufacturer of Cable Tray Polymer - HC1-MR Hesheng Perforated Middle Reducer – Hesheng

Manufacturer of Cable Tray Polymer - HC1-MR Hesheng Perforated Middle Reducer – Hesheng Detail:

Product description

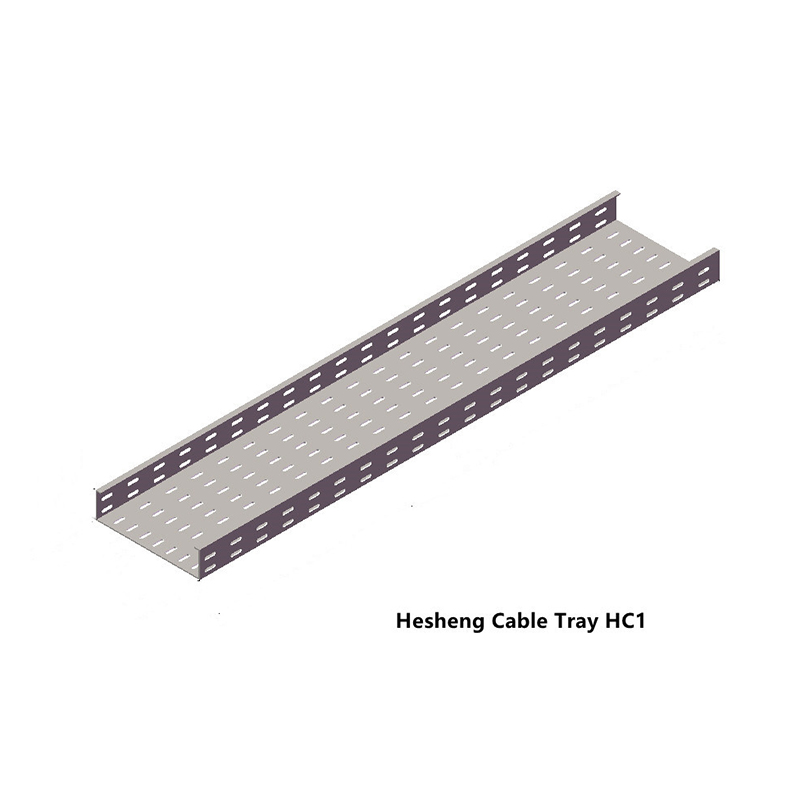

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

Cable management is a key consideration for optimizing system reliability, effective space utilization and scalability. Hesheng group offer industry, leading cable tray systems as part of comprehensive, integrated Data center solutions to effectively manage and protect high-performance communication, computing and power cables.

Cable tray- is a safe and economical solution for supporting requirements of electric power, signal, control, instrumentation and communication cables. Fabricated in numerous styles (wire mesh, ladder, ventilated trough, channel, and solid-bottom) and sizes, cable tray provides the greatest versatility among cable support systems, while offering savings of up to 84 percent in labor costs.

Moreover,H.S. also develop various accessories for our range which are used for support & installation of cables over the cable trays.

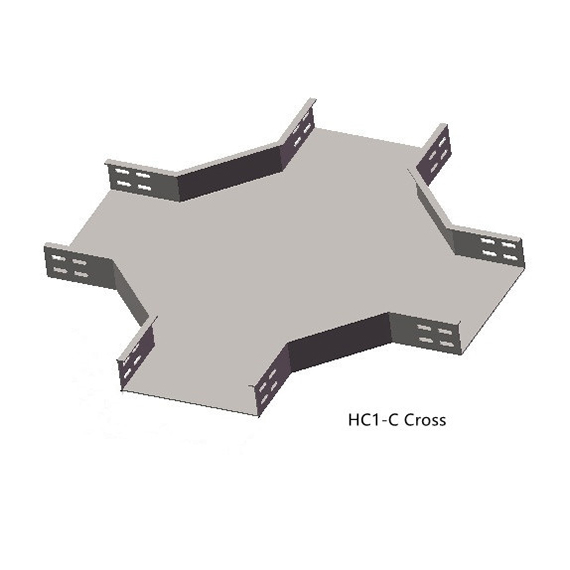

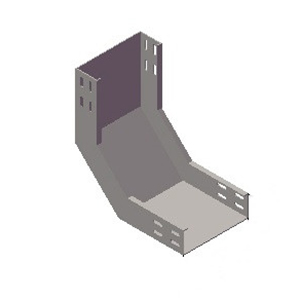

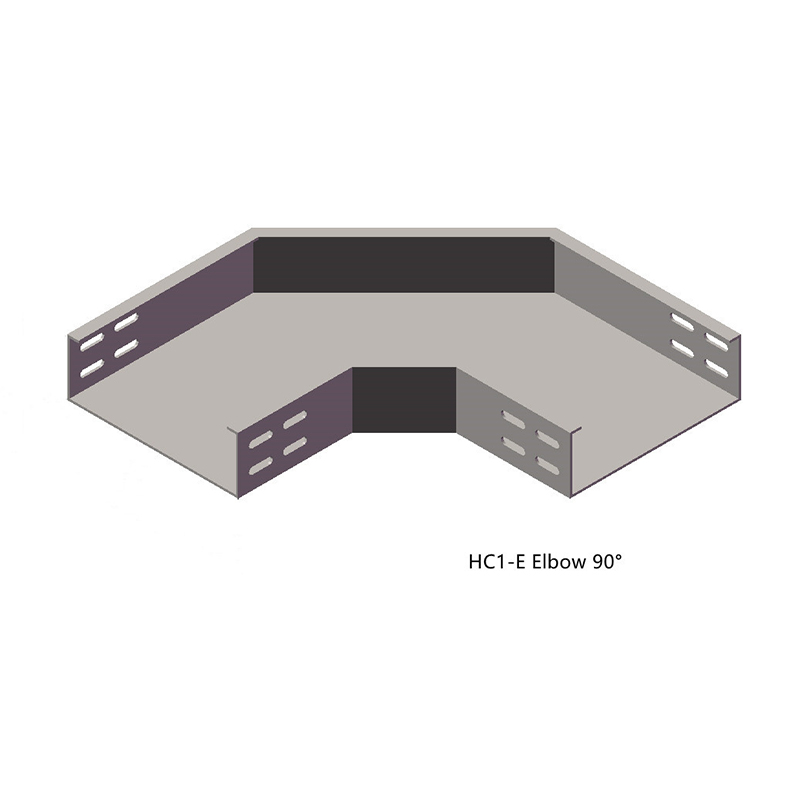

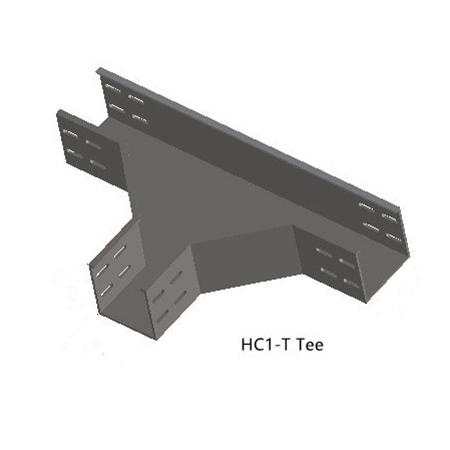

H.S.offer a wide range of components of perforated cable trays.Middle Reducer is one of the components,used as reducer connector.

These perforated cable trays are offered in different materials , generally fabricated in mild steel, Pre-galvanized, Hot-dip Galvanized,Stainless Steel,Aluminium,Fiber Reinforced Plastic, Plain Steel with powder coated.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

Product Specifications

|

Oerdering Code |

W1(mm) |

W2(mm) |

H(mm) |

|

|

HC1-MR |

HC1-MR-100-50 |

100 |

50 |

50 |

|

HC1-MR-150-50 |

150 |

50 |

50 |

|

|

HC1-MR-200-50 |

200 |

50 |

50 |

|

|

HC1-MR-150-100 |

150 |

100 |

50 |

|

|

HC1-MR-200-100 |

200 |

100 |

50 |

|

|

HC1-MR-250-100 |

250 |

100 |

50 |

|

|

HC1-MR-200-150 |

200 |

150 |

50 |

|

|

HC1-MR-300-150 |

300 |

150 |

50 |

|

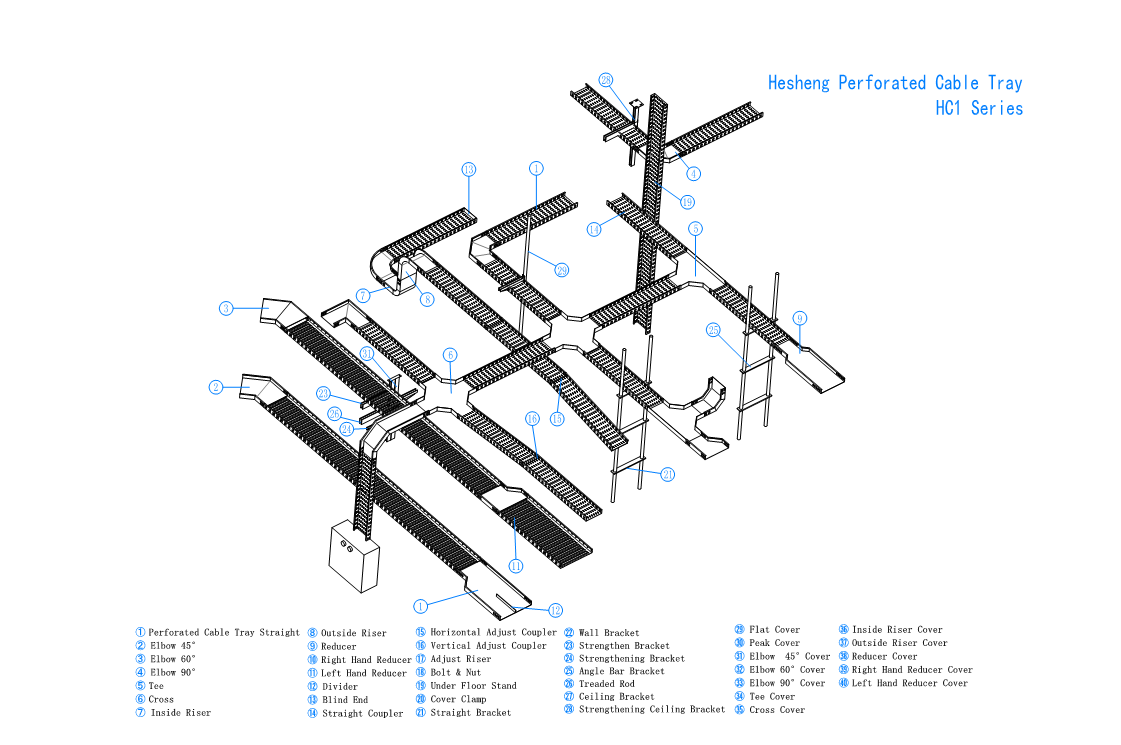

Schematic diagram of the Cable Tray space layout

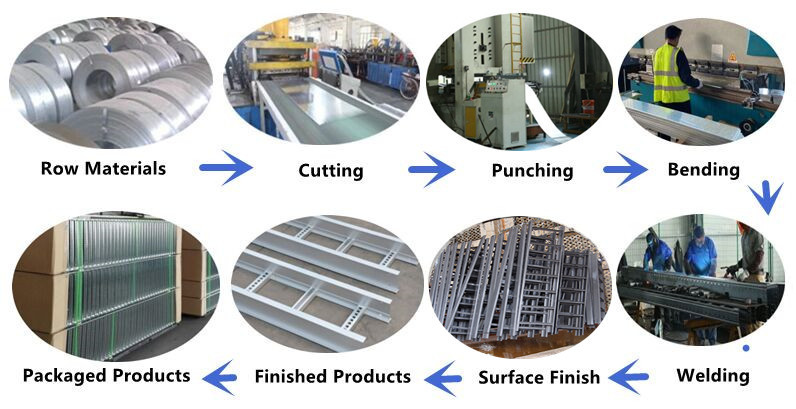

Production Process

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing and Delivery for Cable tray

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

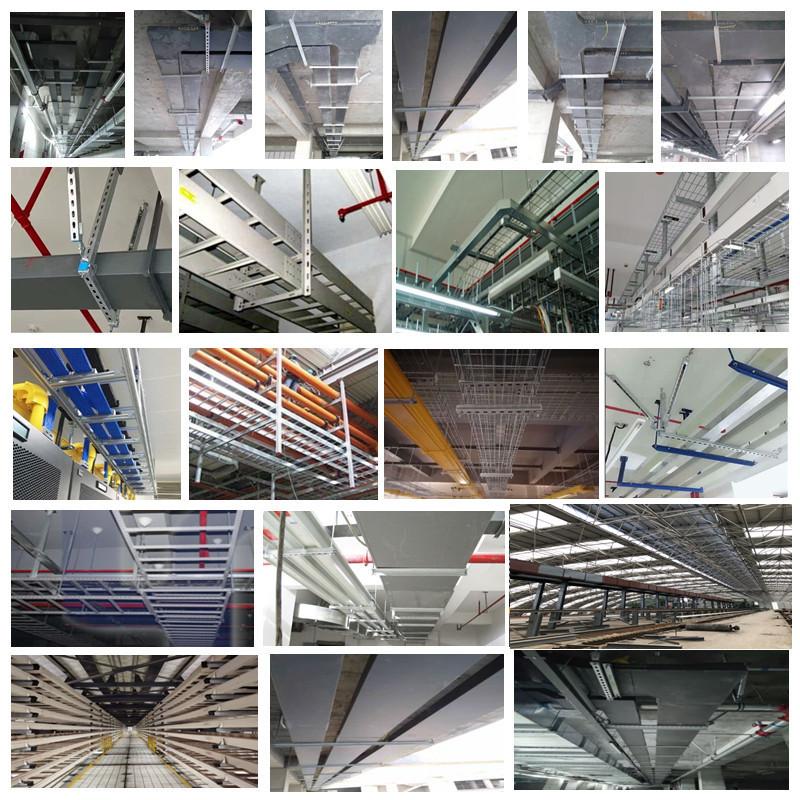

Installation case on site for Hesheng cable support system

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

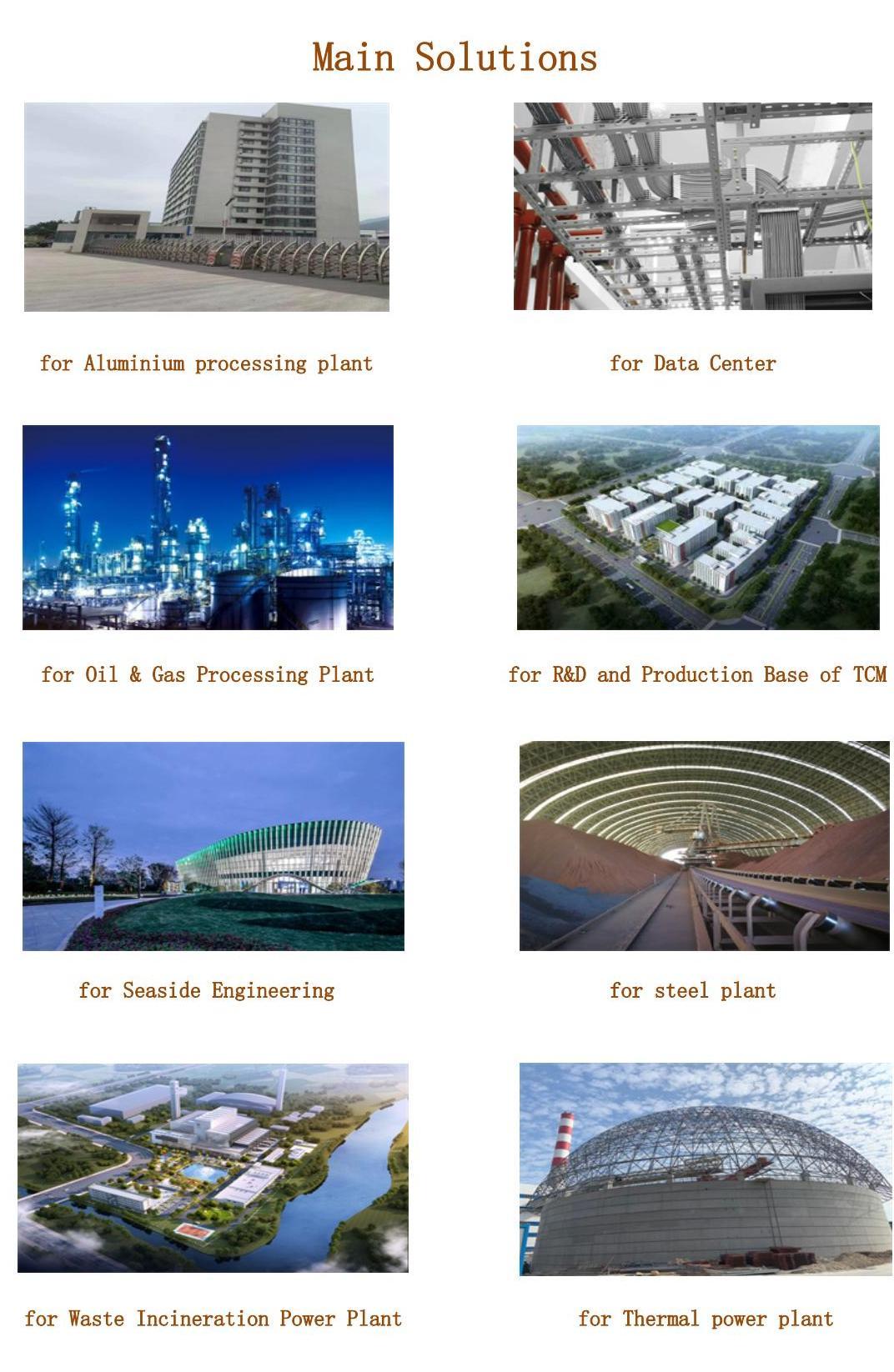

Product application program

Actual Test on Site

Certificate

Installation case on site for perforated cable tray HC1

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Manufacturer of Cable Tray Polymer - HC1-MR Hesheng Perforated Middle Reducer – Hesheng , The product will supply to all over the world, such as: Holland, Cyprus, UAE, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!