Cable tray bracket spacing specification requirements

1, cable tray cable horizontal laying, in the cable of the first, last, corner and every 3 to 5m apart for stabilization.

2, when the cable tray is laid horizontally, the support spacing is usually 1.5 to 3m, when laid vertically, the spacing fixed on the building structure of the house should be less than 2m.

3, two groups of cable trays in the same height parallel surface laying, the spacing is not less than 0.6m.

4, cable tray and electricity facilities crossing, the spacing is not less than 0.5m.

Precautions to be taken when installing the cable tray

1, appearance check

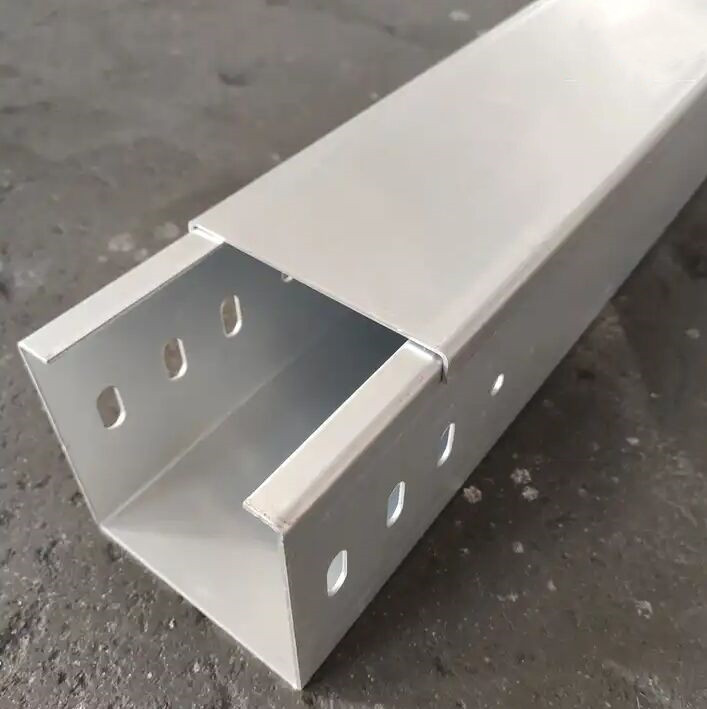

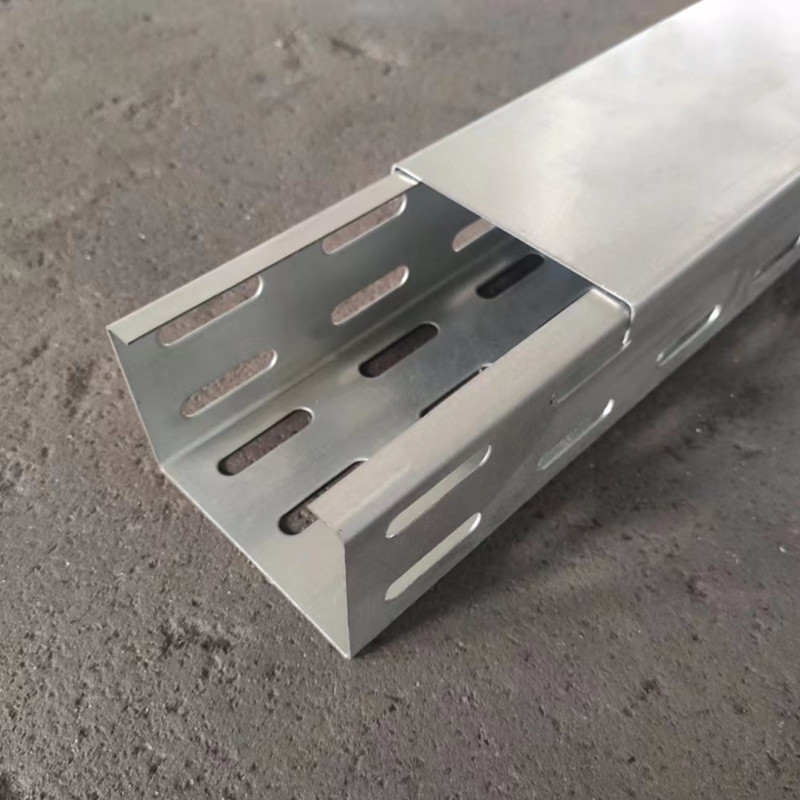

When the cable tray is transported to the construction site, it should be submitted to the factory certificate of the product, provincial and municipal quality supervision report, and technical appraisal documents and some other relevant information. If it is hot-dip galvanized, the surface should be uniform, so that there is no over-burning, hanging ash, unplated full zinc operation. Electrostatic spraying to achieve a smooth and even surface, no blistering, no skinning, no distortion of the status quo. No burr cable tray to achieve a uniform surface welding, no leakage of welding, cracks, burn through and some other defects.

2, the installation position of the cable tray

In the cable tray for horizontal laying, the height is generally not less than 2.5m, in order to dissipate heat, maintenance of some of the needs of the multi-layer laying time to remember to stay reserved space, the net distance should be done in accordance with the relevant provisions.

3, the installation of support hangers

In the cable tray in the quality of the support bracket, should be done in line with the relevant technical standards of the horizontal laying, spanning the support for 1.5-3m vertical laying, fixed spacing can not be greater than 2m, two neighboring cable tray bracket horizontal height difference can not be a difference of 10mm, the vertical centerline deviation can not be greater than 20mm.

Hesheng Group manufacture and export all kinds of cable tray/ cable ladder /perforated cable tray/ cable trunking and wire mesh cable tray with more than 16 years experience, and our cable trays are Nema, UL and CE certified. If interested in any cable tray , kindly contact us via laddertray@163.com , we can send you our full range cable tray catalog if necessary.

4, pay attention to environmental conditions

When the cable support goes through the wall from the natural environment under normal conditions to the fire safety and explosion-proof natural environment, the corresponding sealing equipment should be installed on the wall. When the cable tray from the room through the wall to the outdoor, in the outside of the wall should be used to waterproof and rainproof specific measures. When the cable tray passes through the wall from the room to the outdoor high altitude installation, the cable tray should be firstly tilted downward to increase the appropriate amount of spacing, and then built upward to prevent the rainwater from flowing into the room along with the cable tray.

Post time: Nov-30-2023