Galvanized cable tray has four points of excellent environmental performance and three points of self-maintenance matters

Galvanized cable tray is the use of electrolytic equipment will be cable tray after degreasing, pickling, after the composition of zinc salts into the solution, and connected to the negative electrolytic equipment, the opposite side of the cable tray placed in the zinc plate, connected to the positive electrolytic equipment connected to the power supply, the use of electric current from the positive to the negative directional movement will be in the cable tray on the deposition of a layer of zinc, galvanized cable tray is the first processing after galvanization, is that it plays a corrosion-resistant effect.

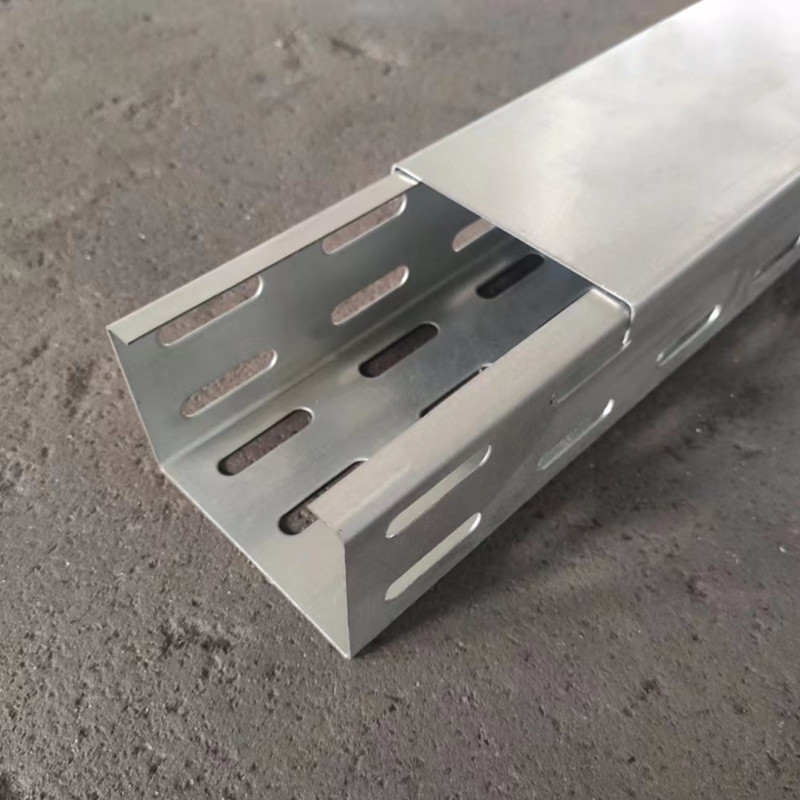

There is a lot of knowledge about galvanized cable tray:

Galvanized cable tray has four excellent environmental performance

1, the composition does not contain Ph, cr, Hg and other heavy metals;

2, attributed to the thick film type material, thixotropic properties, after sufficient mixing, less or no diluent, can be painted construction. As galvanized solids content of up to 77%, solid wire, an airless spraying can obtain a higher film thickness, reducing the volatility of organic solvents, reducing drying energy consumption, these are conducive to environmental protection.

3, tested and proven: the vast majority of galvanized solvents and diluents do not contain toluene, ketones, halogenated hydrocarbons and other toxic organic solvents.

4, galvanized cable tray is an alternative to hot dip galvanizing, electric arc (hot) zinc spraying of good materials, to reduce the three wastes, reduce energy consumption, improve environmental protection and social benefits of the role of the more obvious.

We manufacture and exports all kind of cable tray, such as cable trunking, cable ladder, perforated cable tray, wire mesh cable tray or basket cable tray, hinged cable tray or wireway and strut channel. we can send you our cable tray catalog if necessary, kindly contact us via laddertray@163.com

Galvanized cable tray equipment, three points of self-maintenance matters

1, cable trays equipment balancing cylinder action and its oil lubrication system oil circuit, joints and other testing and inspection.

2, cable tray equipment slider and guide rail friction between the more frequent, should make the necessary adjustments more positive, check the joint parts of the lubrication quality and piping to ensure good operation.

3, regular lubrication for the cable tray equipment gear parts: gear box and internal components because of frequent operation damage is more likely to be greater, there is a greater possibility of loosening. When these parts of the noise, you can first lubricate, and then according to the vibration, check the system between the oil injection point of the spit oil volume and pressure test, make appropriate adjustments.

Post time: Jul-31-2023