1.The cable tray is a support for supporting and releasing the cables. Cable trays in the project with a very common, as long as the laying of cables to use the cable trunking, cable containment as a supporting project of the wiring project, there is no special specification guidance, each manufacturer’s specification program lack of universality, therefore, the design and selection process should be based on the type of weak power each system cable, the number of reasonably selected applicable cable trays. Cable duct have a full range, wide application, strength, light structure, low cost, simple construction, flexible wiring, installation standards, beautiful appearance and other characteristics.

2.classification and use

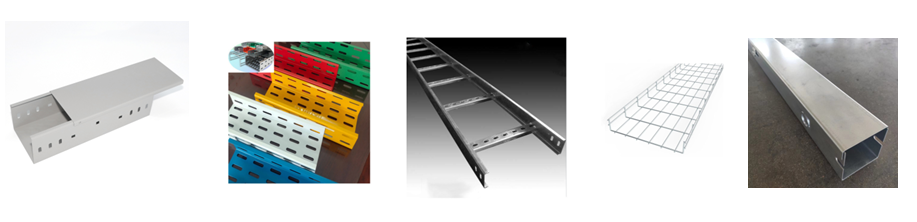

Cable tray is usually divided into trough type cable tray, ladder type cable tray, perforated type cable tray, large span cable tray. Ladder type cable tray is suitable for general laying of larger diameter cables, suitable for high and low voltage internal chain power cables.

Trough cable tray is a fully enclosed cable bridge, most suitable for laying computer cables, communication cables, thermocouple cables and other highly sensitive systems of control cables, etc.

Ladder cable tray has the advantages of light weight, low cost, distinctive shape, easy installation, heat dissipation, good ventilation, etc.. He is suitable for general laying of cables with larger diameters, and for laying of high and low voltage internal chain power cables.

Perforated cable tray is the most widely used in petroleum, chemical, light industry, telecommunications, etc., that is, suitable for the installation of power cables, but also suitable for the laying of control cables.

Large span cable tray can be divided into ladder type, perforated type, trough type. Ladder type cable tray has good ventilation performance, not dustproof, may wish to interfere. The surface treatment of tray type cable tray can be divided into galvanized, electrostatic spraying and hot-dip galvanized according to the needs of users, and special anti-corrosion treatment can be applied in heavy corrosive environment. It is suitable for power cables, control cables, lighting cables and accessories, etc.

3. specifications and market analysis

Cable trays compared to the channel specifications are relatively large, commonly used is a slotted cable bridge, cable tray with cover, but not necessarily with a partition, the same specification of the bridge will have different thicknesses. Generally common thickness in the range of 0.8-3mm, different occasions will use different thickness, for example, 100 * 50 will have four common thickness: 0.8 1.0 1.2 1.5, different thickness of the price will vary greatly, the price difference is mainly affected by the price of steel and the cost of processing.

The greater the width and height of the cable tray, the greater the price difference between adjacent thicknesses. Usually the cable tray will have the national standard thickness, the national standard thickness commonly used 1.0mm, 1.2mm, 1.5mm, 2.0mm. the width of the cable tray is usually below 1.2 meters, the height is usually below 0.25 meters, the length of each is 2 meters, the surface of the bridge will generally do anti-corrosion treatment, usually electro-galvanized (cold plating), hot dip galvanized, painted, powder coating, other organic inorganic coatings Coating. Hot-dip galvanized and cold-dip galvanized are the most commonly used, and the price is higher for electro-galvanized, and cold-dip galvanized is almost 1 times more expensive than hot-dip galvanized.

According to the different occasions will use different materials of the cable tray, commonly used steel, aluminum, 201 stainless steel, 304 stainless steel, etc.. Galvanized steel is the most commonly used, aluminum alloy material is about 1.5 times more expensive than galvanized steel; 201 stainless steel and aluminum alloy material price is about the same; 304 material is 2 times more than 201 material, is 3 times more than galvanized steel material.

In the process of using the cable trays, there will be some accessories to connect the cable trays, commonly used to have a bend and tee, in general, the unit price of the bend is 1.2 times the price of the same specification per meter cable tray, tee is 1.3 times the price of the same specification per meter of cable trays.

4.the factors that affect the price

The parameters that affect the price of the cable tray is generally the specification, thickness and material, the specification is also the width and height.

Post time: Feb-08-2023