In the realm of cable management, HS perforated cable tray stands out as an exemplary solution for supporting and protecting electrical cables and wiring systems in various industrial, commercial, and residential settings. This product is designed not only to uphold a substantial amount of cables but to ensure an organized and accessible arrangement that is paramount for maintenance and system updates.

Load Capacity

HS Perforated cable trays are engineered to meet stringent industry standards, delivering a robust structure capable of carrying significant cable loads. The load-bearing capacity of these trays is determined by the material used, the thickness of the metal, and the overall design. Typically, these trays can support a wide range of loads from light telecommunications cables to heavy-duty power lines, ensuring versatile applicability for projects of all scales.

Advantages

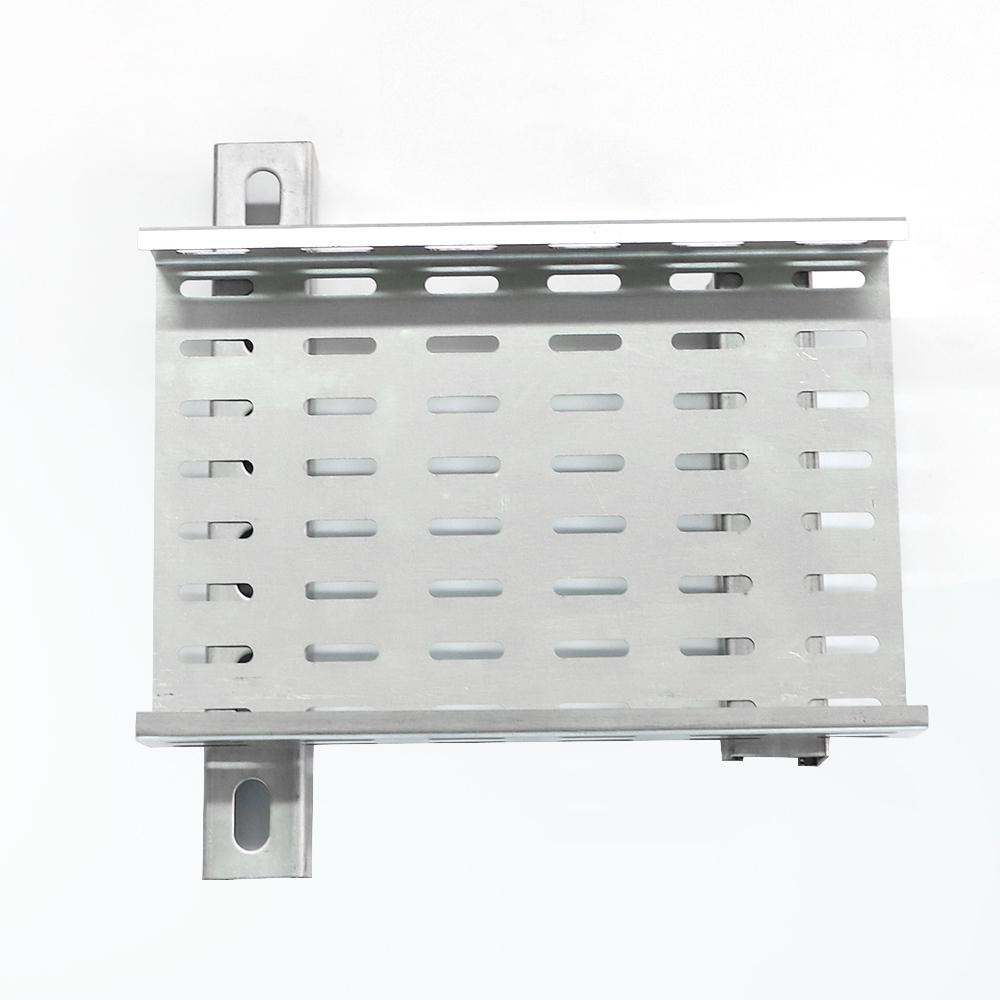

The perforated design offers a plethora of benefits. The openings in the tray provide adequate ventilation to the cables, which helps in dissipating heat and reduces the chances of overheating. This factor is crucial in maintaining the optimal performance of cables and extends their lifespan. Additionally, this feature aids in the prevention of dust accumulation and moisture buildup, further safeguarding the cabling infrastructure.

Self-Weight

Crafted with efficiency in mind, HS perforated cable trays are lightweight without compromising on strength. Their self-weight is less compared to solid-bottom trays, making them easier to handle, transport, and install. This lightweight nature reduces the structural load on buildings and supports frameworks, making them an excellent choice for both new constructions and upgrades to existing structures.

Energy Efficiency

One seldom discussed yet significant advantage of HS perforated cable trays is their contribution to energy efficiency. By enabling better airflow, these trays help maintain a cooler operating environment for cables, which can reduce the need for additional cooling systems and save on energy costs. Moreover, the ease of installation and the reduced weight contribute to less energy consumption during the construction phase and throughout the lifecycle of the cable management system.

Durability and Maintenance

HS Perforated cable trays are designed with durability in mind. Often made from high-quality materials such as galvanized steel, stainless steel, or aluminum, they resist corrosion and can withstand harsh environmental conditions. They are also easy to inspect and clean due to their open design. This accessibility simplifies routine maintenance and troubleshooting, minimizing downtime and labor costs associated with cable management.

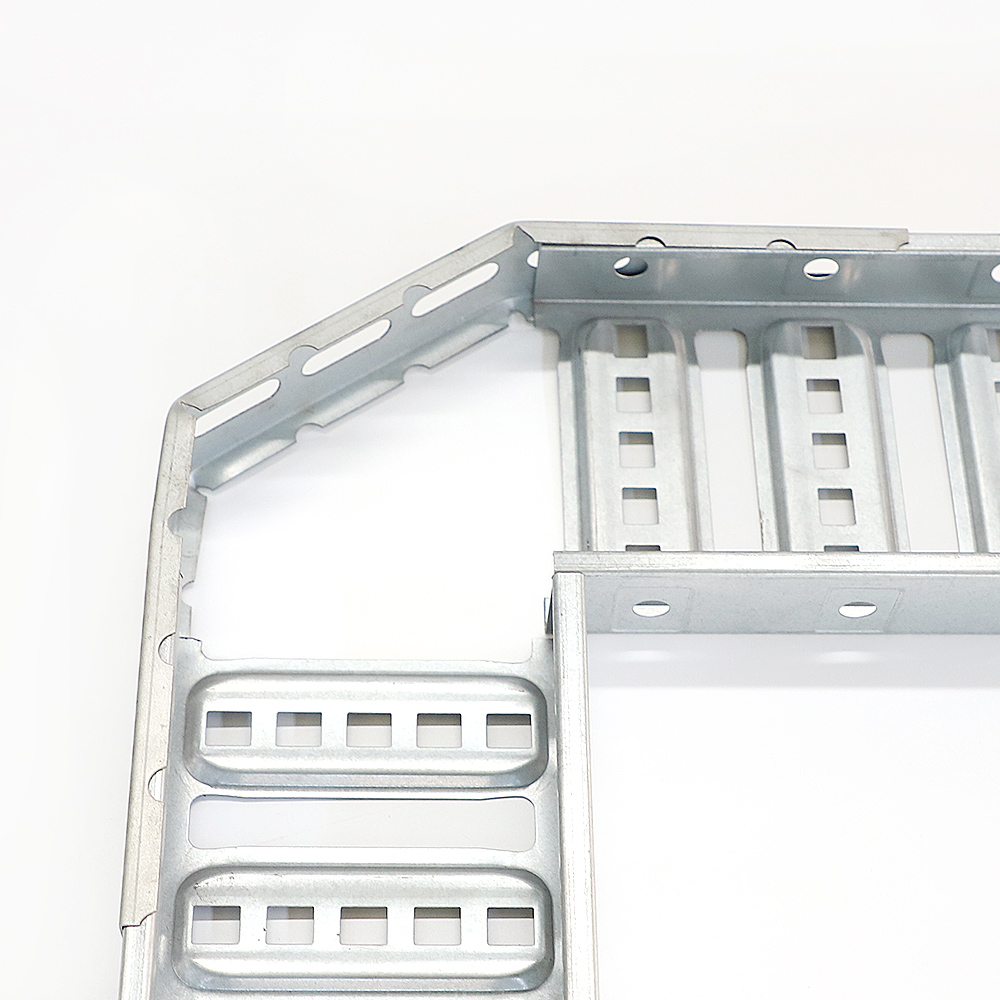

Versatility

The modular nature of the HS perforated cable tray system makes it a highly adaptable solution. Available in various sizes, shapes, and finishes, these trays can be customized to fit specific project requirements and aesthetic preferences. Whether it’s adapting to complex routing needs or integrating with existing structures, perforated cable trays prove to be a versatile and reliable choice for cable management.

Conclusion

HS Perforated cable trays represent a culmination of strength, energy efficiency, and smart design. They provide an economical, durable, and flexible solution for managing cables that cater to an array of industries and applications. By combining load-bearing capacity, lightweight construction, and the advantages of a more efficient, well-ventilated system, these trays stand out as a superior choice for modern infrastructure needs. As technology advances and the demand for reliable cable management increases, perforated cable trays are poised to meet and exceed these evolving requirements.

Post time: Jan-19-2024