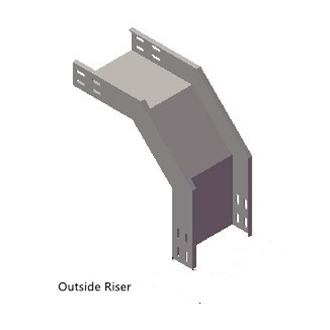

Quality Inspection for Trough Cable Tray - HC1-OR Hesheng Perforated Outside Riser – Hesheng

Quality Inspection for Trough Cable Tray - HC1-OR Hesheng Perforated Outside Riser – Hesheng Detail:

Product description

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

Perforated cable tray is a kind of cable tray with holes on bottom sheet and side rails for laying power and signal cables for the purpose of distributing electricity, signaling in industrial plants, department stores, gyms, hospitals, airports and other industries.

Perforated cable trays have holes on bottom to provide enough ventilation and position for cable lines. Anti-corrosion, fire, moisture due to the pre-galvanized, hot-dipped powder coated, epoxy coated finish. The difference between raceway and cable tray is that the raceways generally mount on a wall in a room where power and communications cables are terminated. Cable trays are usually overhead or under raised floors but carry open wiring. They are used to distribute cables from the source to the point of use.

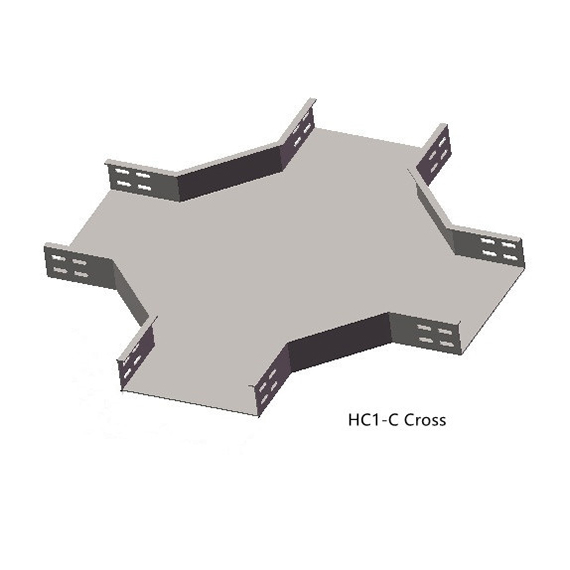

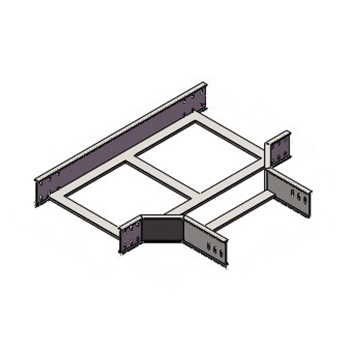

H.S.offer a wide range of components of perforated cable trays. Outside Riser is one of the components,used as vertical upward bend.

These perforated cable trays are offered in different materials , generally fabricated in mild steel.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

Product Specifications

|

Oerdering Code |

W(mm) |

H(mm) |

|

|

HC1-OR |

HC1-OR-50-50 |

50 |

50 |

|

HC1-OR-100-50 |

100 |

50 |

|

|

HC1-OR-150-50 |

150 |

50 |

|

|

HC1-OR-200-50 |

200 |

50 |

|

|

HC1-OR-250-50 |

250 |

50 |

|

|

HC1-OR-300-50 |

300 |

50 |

|

|

HC1-OR-400-50 |

400 |

50 |

|

|

HC1-OR-450-50 |

450 |

50 |

|

|

HC1-OR-500-50 |

500 |

50 |

|

|

HC1-OR-600-50 |

600 |

50 |

|

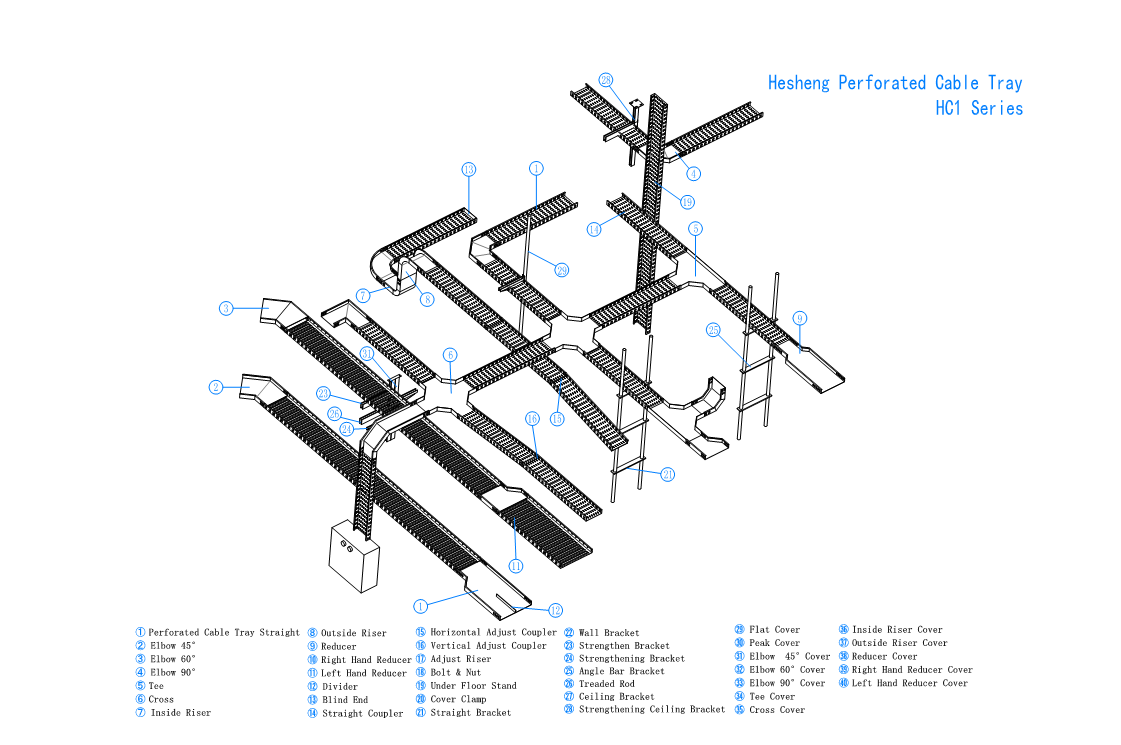

Schematic diagram of the Cable Tray space layout

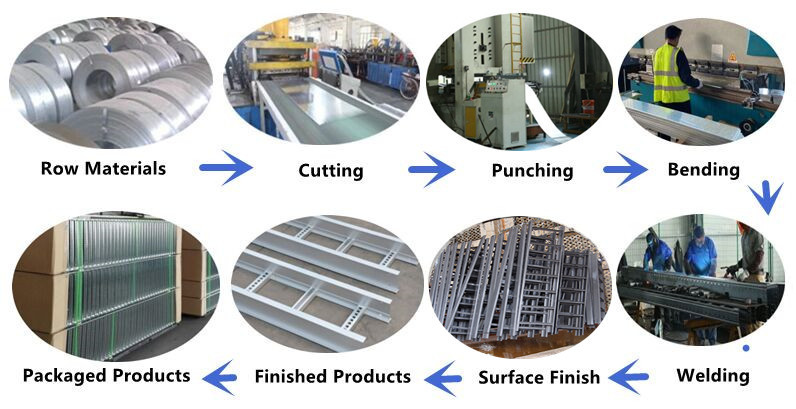

Production Process

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing and Delivery for Cable tray

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

Installation case on site for Hesheng cable support system

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

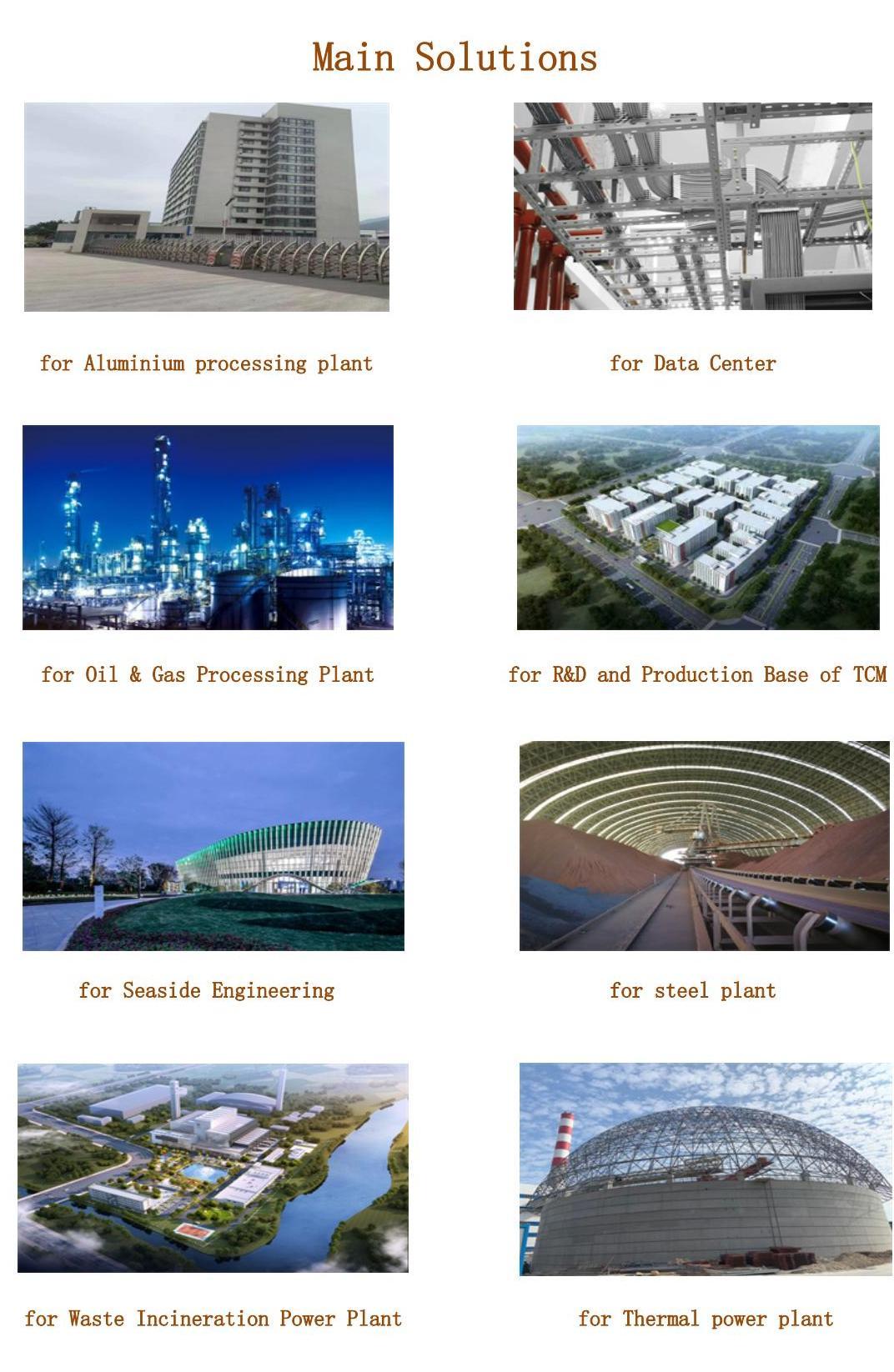

Product application program

Actual Test on Site

Certificate

Installation case on site for perforated cable tray HC1

Product detail pictures:

Related Product Guide:

"Quality very first, Honesty as base, Sincere assistance and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Quality Inspection for Trough Cable Tray - HC1-OR Hesheng Perforated Outside Riser – Hesheng , The product will supply to all over the world, such as: Russia, Turkey, Burundi, We aim to become the modern enterprise with the commercial ideal of "Sincerity and confidence" and with the aim of "Offering customers the most sincere services and best quality products". We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.