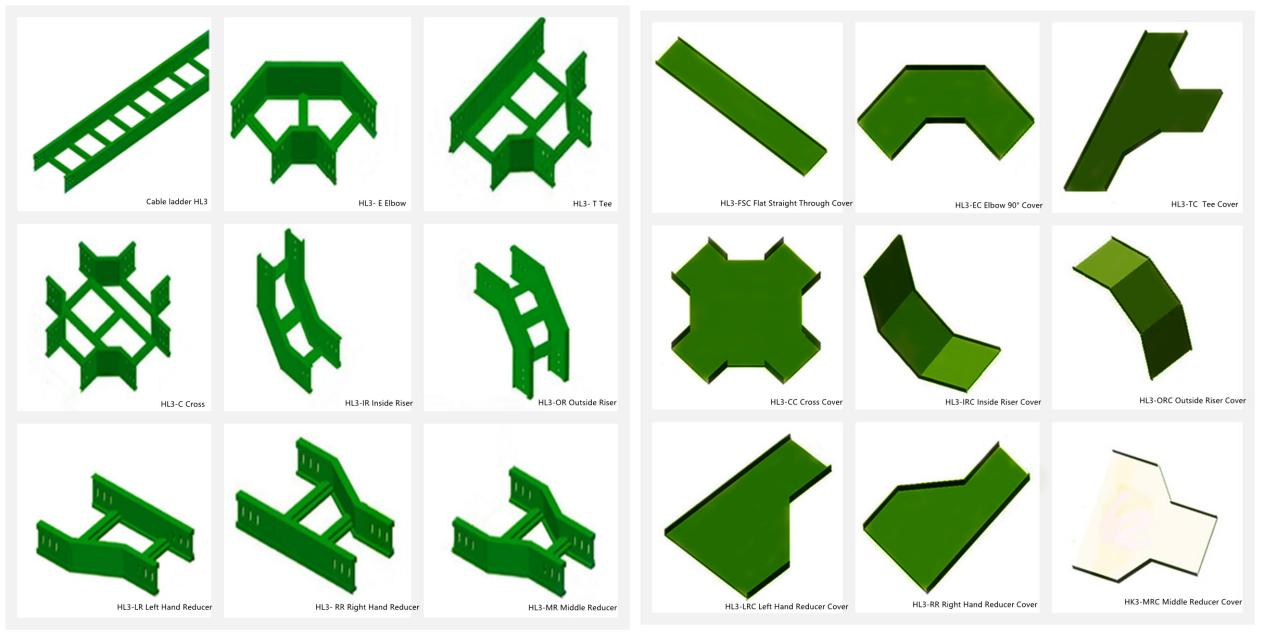

HL3-C Hesheng Metal Four Way Cross for Cable Ladder HL3

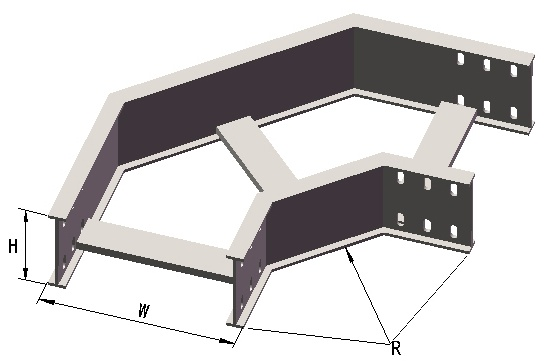

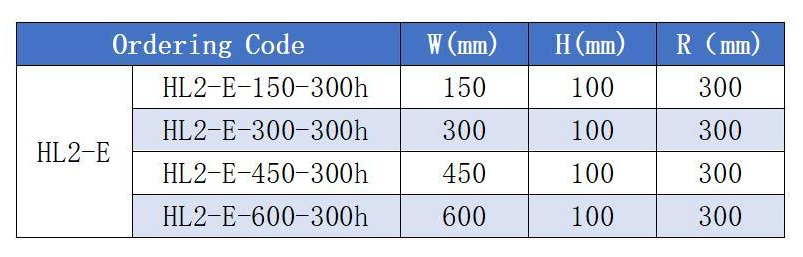

Hesheng HL3-E Elbow90°

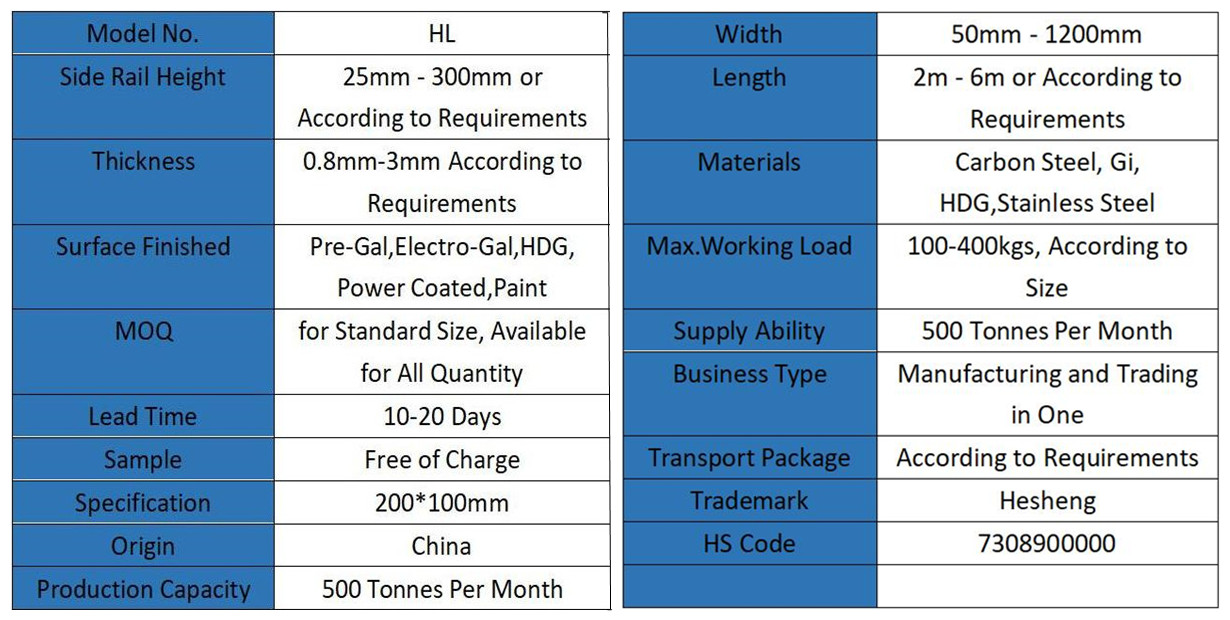

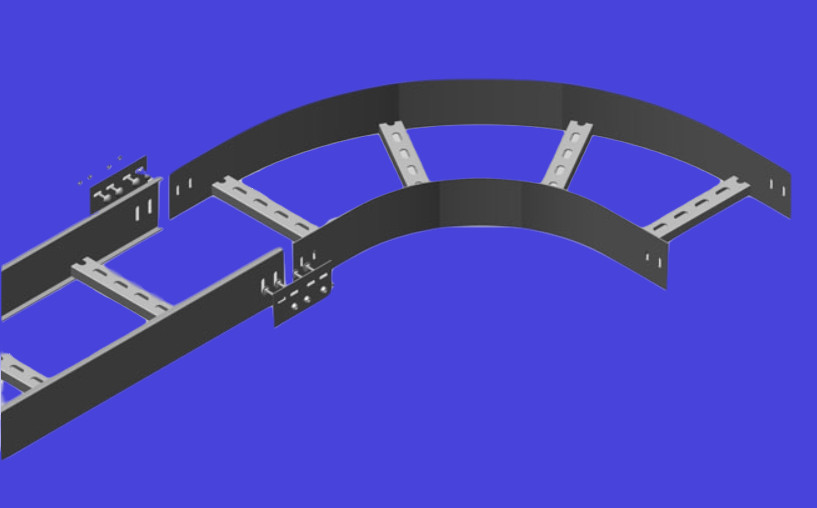

Hesheng Cable Ladder is an economical wire management system designed to support and protect electrical wires and cables. Cable Ladder is permitted in a variety of indoor and outdoor applications. Ladder tray can withstand heavy rigor and harsh environments with heavy hot dip galvanized steel, fiberglass, and aluminum options. Cope rungs are fastened to the side members by an exclusive swaging process. This method insures superior mechanical and electrical connection and maximum access to cables even in narrow or divided cable trays.

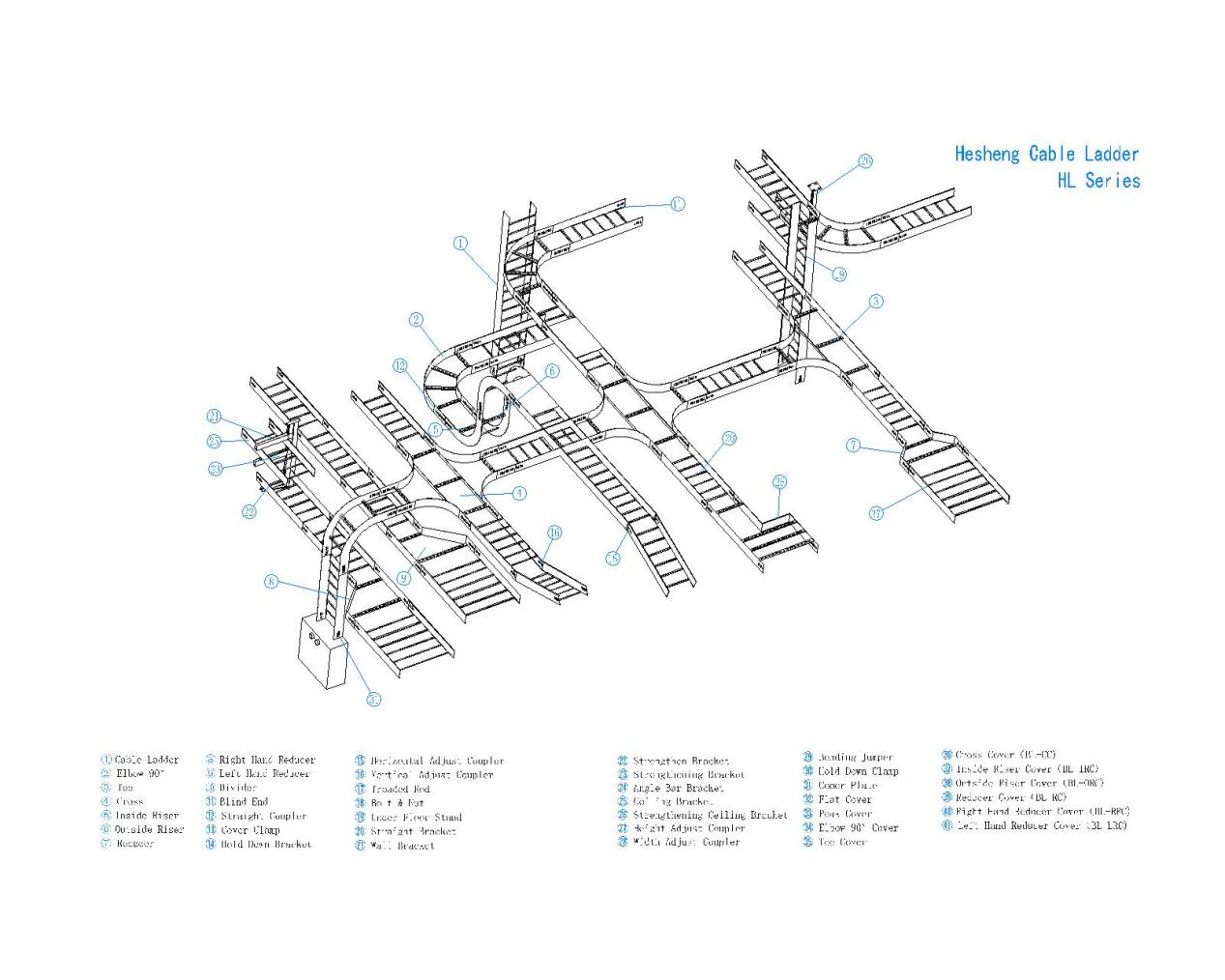

Hesheng Group provides a series of cable supports:

Wire Mesh Cable Tray, Perforated Cable Tray, Cable Trunking, Cable Ladder, Wire way, Strut Channel and accessories.A range of nearly twenty fittings makes the system totally customizable to accommodate any kind of tricky configuration. Users can achieve design flexibility with numerous sizes of horizontal and vertical elbows, adjustable elbows, cross pieces, tees, reducers, and branches. Cope customer service experts can help customers select the right fittings for specific applications.

Elbow90°is one of the components used as the connector in the place of the upright corner. 4-way cross is one of the components used as the connector of the 4 branches , HL3-C Cross is the same as the straight through part with the strengthening cross bars and much larger cable load than HL1 & HL2 Cable ladder.

Our products can be widely used in construction, energy, electricity, plant. We passed the ISO 9001 quality management system certification, UL Certificate (U.S.A.), and CE Certificate (E.U.)

Cable Ladder permits much greater spacing between support hangers than for most other systems,providing savings in support costs and labor installation,

Standard finish of H.S. Cable Ladder HL3 as below,customize available and in varying width and load depth for many applications including primary service entrance, main power feeders, branch wiring, instrument and communications cable..,

· H--- Hot Dip Galvanized.

· G--- Pre-galvanized steel .

· S4-- Stainless Steel SS304.

· S6-- Stainless Steel SS316.

· P--- Powder Coated.

· A--- Aluminium.

· FRP-Fiber glass Reinforced Plastics/ GRP.

Supports Advantages:

· From light to heavy load

·Good lateral stability ·No nasty sharp edges

·Open profiles provide better corrosion protection

·Reduced weight without loosing strength

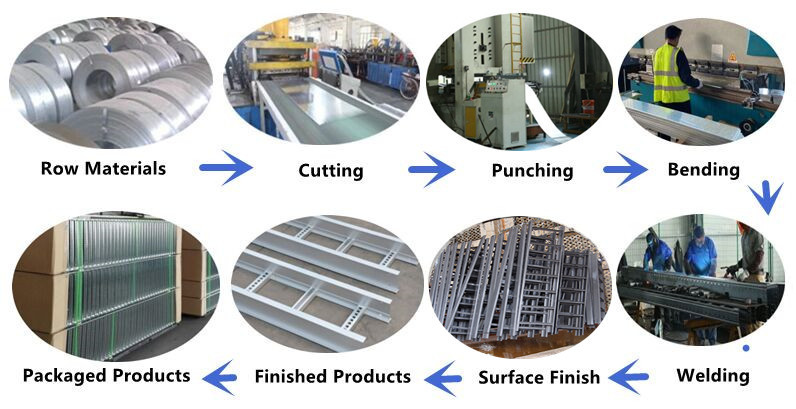

Production line for Metal Cable Tray Here is processing line of cable support system and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

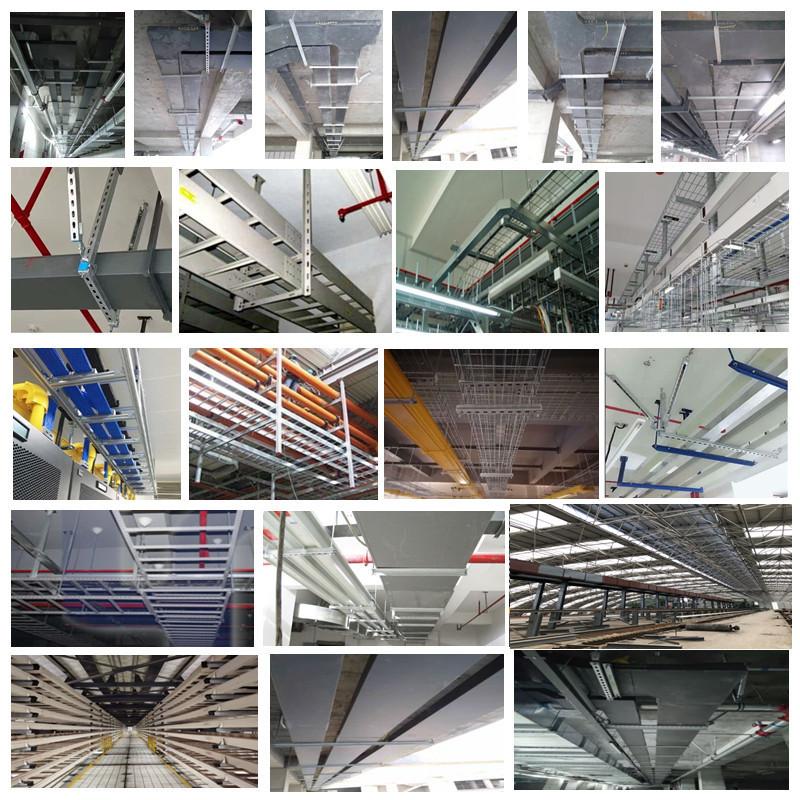

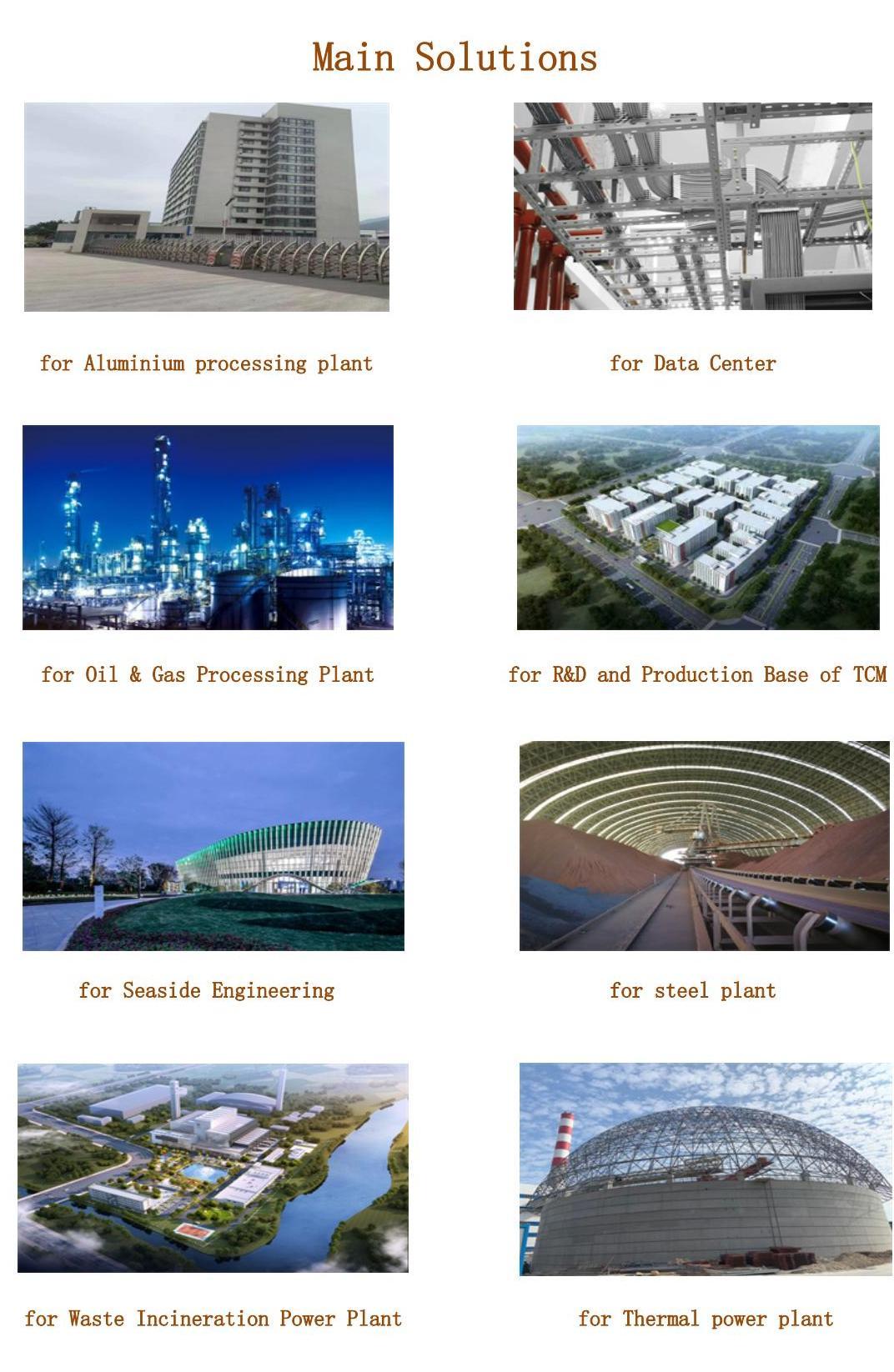

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied for the Aluminium Processing Plant , Steel Plant , R&D and Production Base of TCM Thermal Power Plant, Data Center ,Seaside Engineering, Oil & Gas Downstream, Waste Incineration, Power Plant.

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |