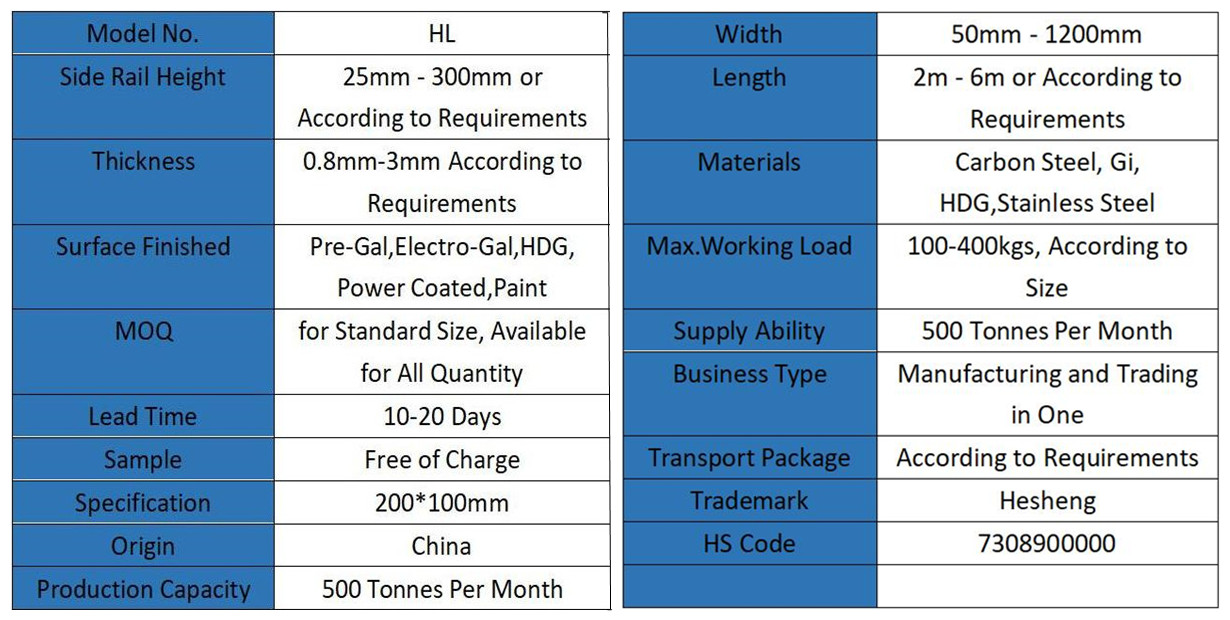

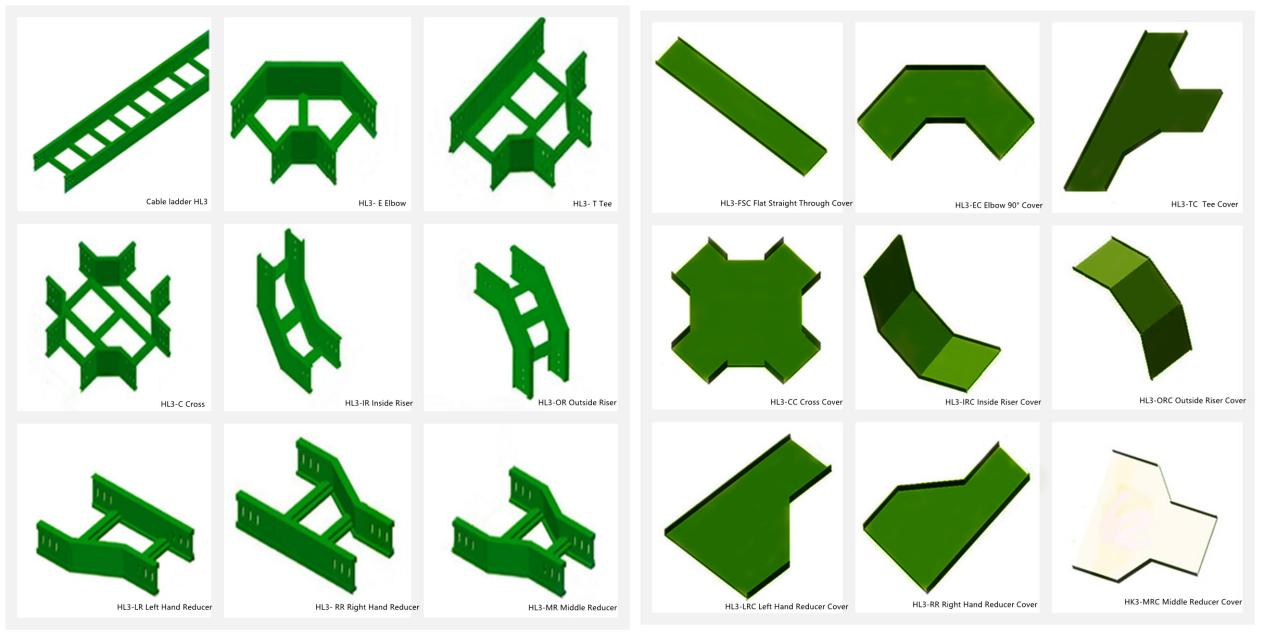

HL3-T Hesheng Metal Alumnium Alloy Tee for Cable Ladder HL3

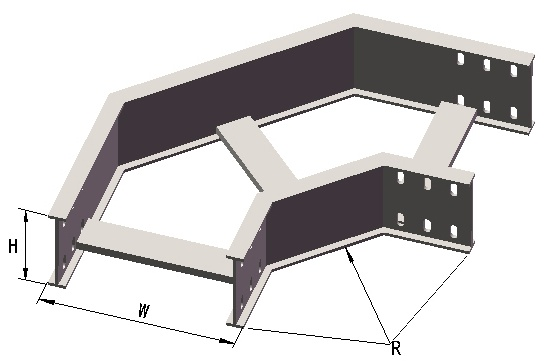

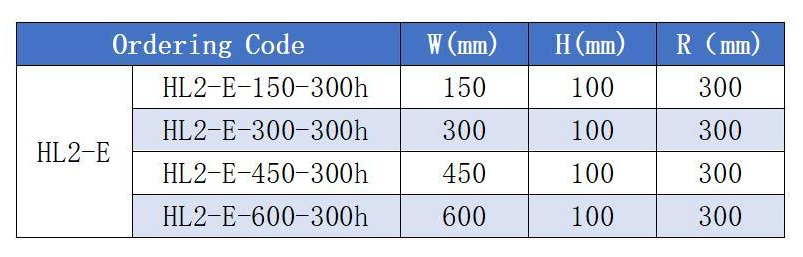

Hesheng HL3-E Elbow90°

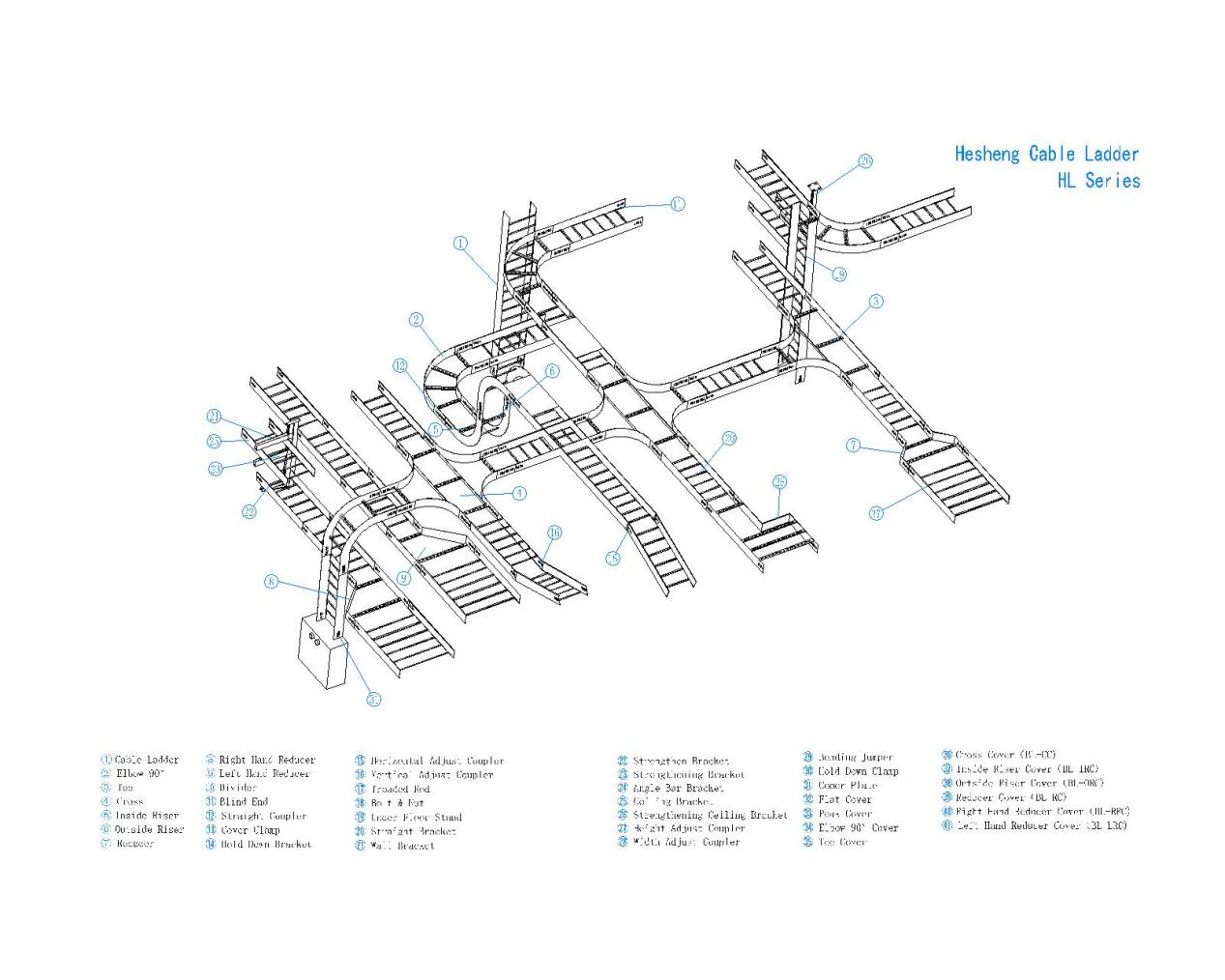

Hesheng Cable Ladder are designed to carry heavier cable loads in the comparison with the standard perforated cable trays. This product group offers easiness in vertical installment. On the other hand the form of cables ladders offers natural.

Ladder

Formed side rails are welded to 15⁄8 in. wide rungs to provide maximum rigidity and strength. Rung design includes exclusive cable tie slots on 1 in. centers.

Ventilated

A fabricated structure consisting of integral or separate longitudinal rails and a bottom having openings sufficient for the passage of air and utilizing 75% or less of the plane area of the surface to support cables.

The maximum open spacings between cable support surfaces of transverse elements do not exceed 102 mm (4 in.) in the direction parallel to the tray side rails (rung to rung).

Solid trough

Solid sheet welded to steel side rails below rungs. This design offers added cable protection.

Wire Mesh Cable Tray, Perforated Cable Tray, Cable Trunking, Cable Ladder, Wire way, Strut Channel and accessories.H.S. also offers a wide range of components of cable ladder, Elbow90°is one of the components used as the connector in the place of the upright corner. HL3-E Elbow is the same as the straight through part with the strengthening cross bar and much larger cable load than Hl1 & HL2 cable ladder.

Our products can be widely used in construction, energy, electricity, plant. We passed the ISO 9001 quality management system certification, UL Certificate (U.S.A.), and CE Certificate (E.U.)

• Combined benefits of solid and ladder but offers additional support that ensures cables can be secured and uniformed;

• Protection from dust, water, or falling debris;

• Full ventilation, ensures that heat produced in the cable’s conductors effectively dissipate and no moisture accumulation;

• Easy access to cables from the top or bottom;

• Maximum protection against electromagnetic or radio-frequency interference;

• Secures and shields sensitive circuits;

• Horizontal bends (90°, 60°, 45° and 30°)

• Horizontal tees and crosses

• Vertical bends (90°, 60°, 45° and 30°)

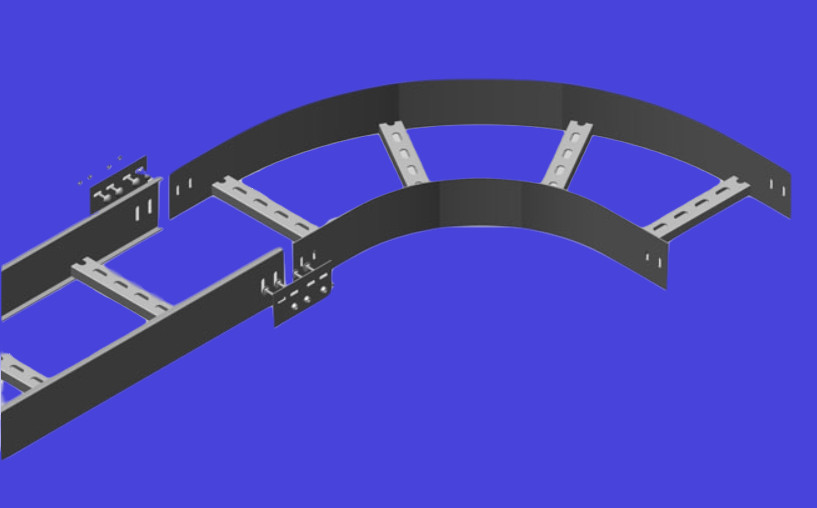

Cable Ladder fittings are used to change the size or direction of the Ladder Tray. The most significant decision to be made in fitting design is radius. The radius of the bend, whether horizontal or vertical, can be zero (non-radius), 12 in., 24 in. or greater on a custom basis. The selection requires a compromise with the considerations being available space, minimum bending radius of cables, ease of cable pulling and cost. The typical radius is 24 inches. Fittings are also available for 30°, 45°, 60° and 90° angles. When a standard angle will not work, adjustable elbows can be used. It may be necessary to add supports to the tray at these points.

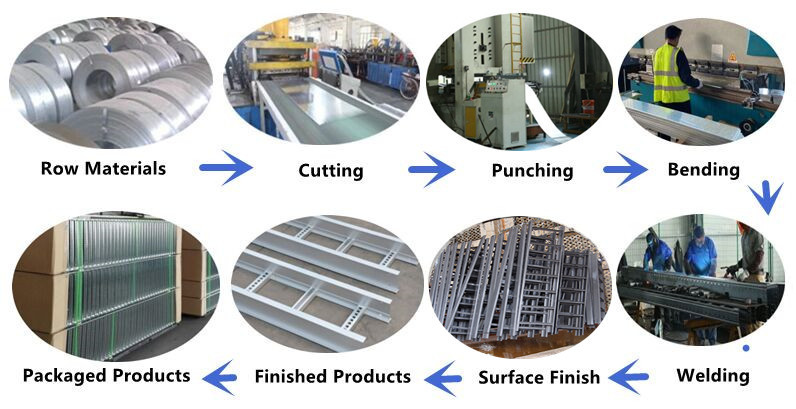

Production line for Metal Cable Tray Here is processing line of cable support system and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

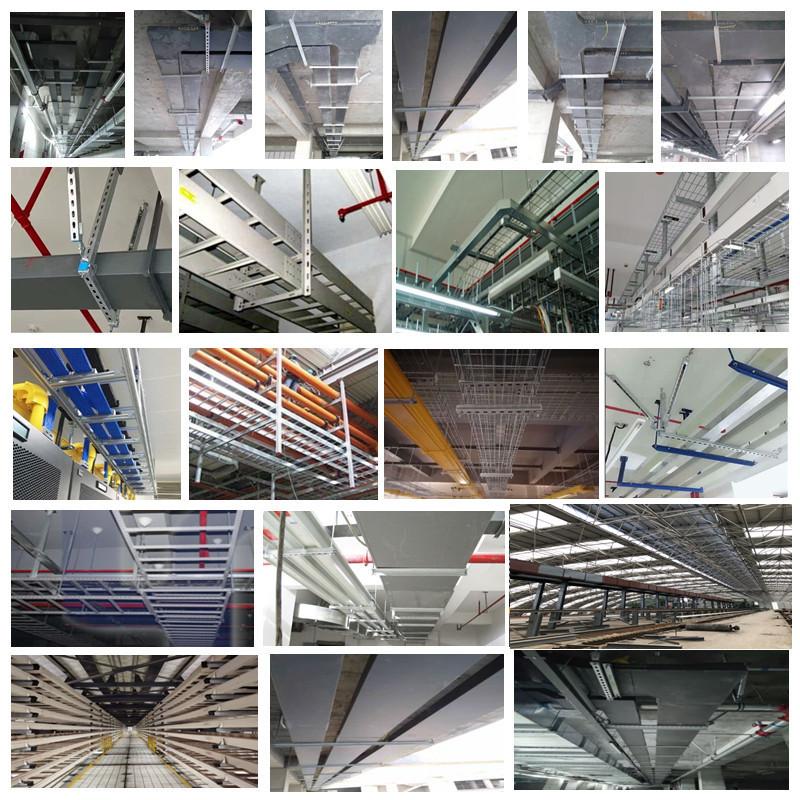

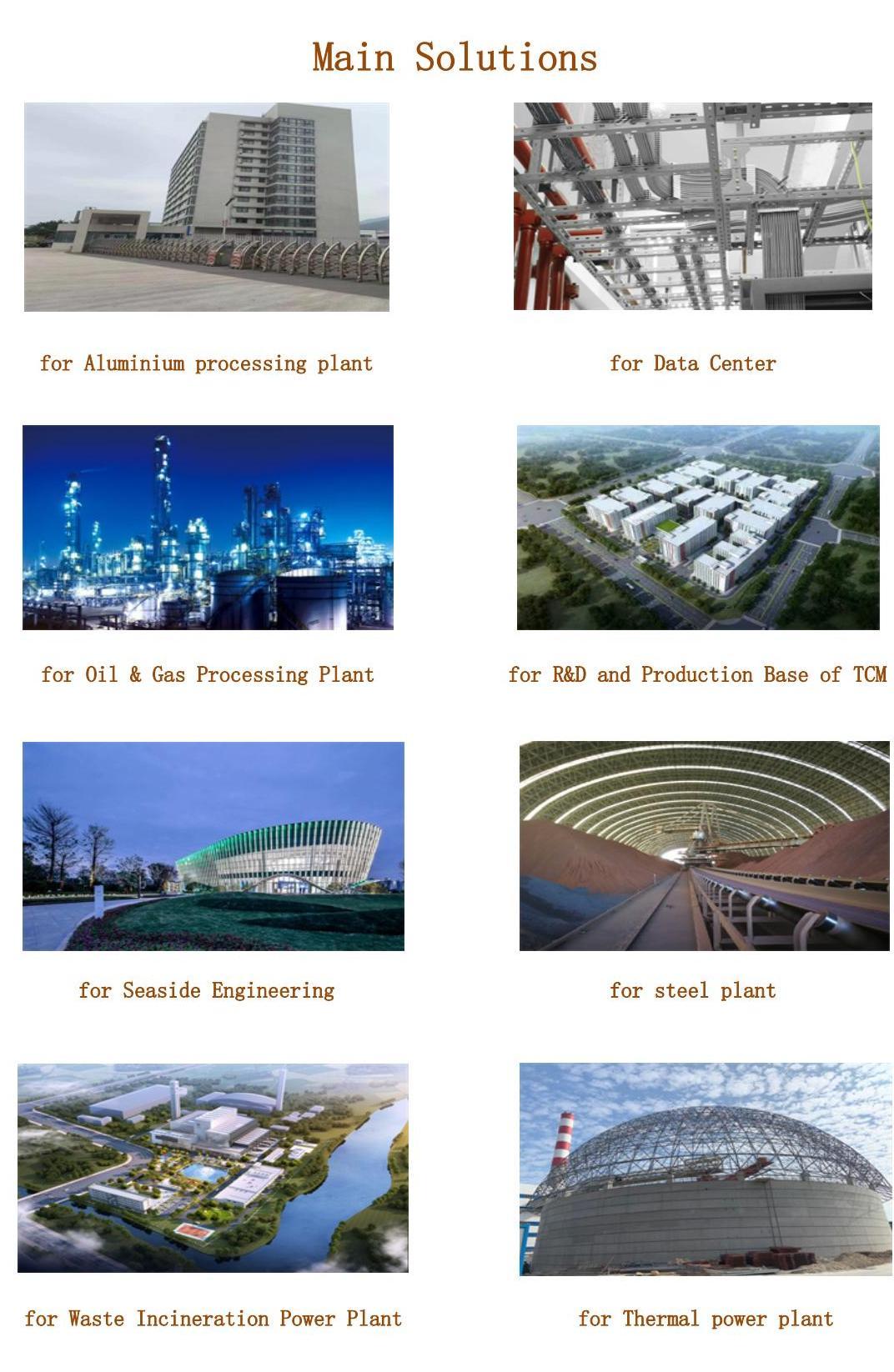

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied for the Aluminium Processing Plant , Steel Plant , R&D and Production Base of TCM Thermal Power Plant, Data Center ,Seaside Engineering, Oil & Gas Downstream, Waste Incineration, Power Plant.

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |