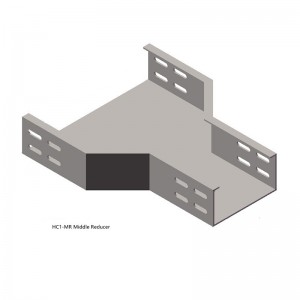

Polymer Alloy plastic (PVC )Upper Left Corner Tee with the chemical structure of whisker modified

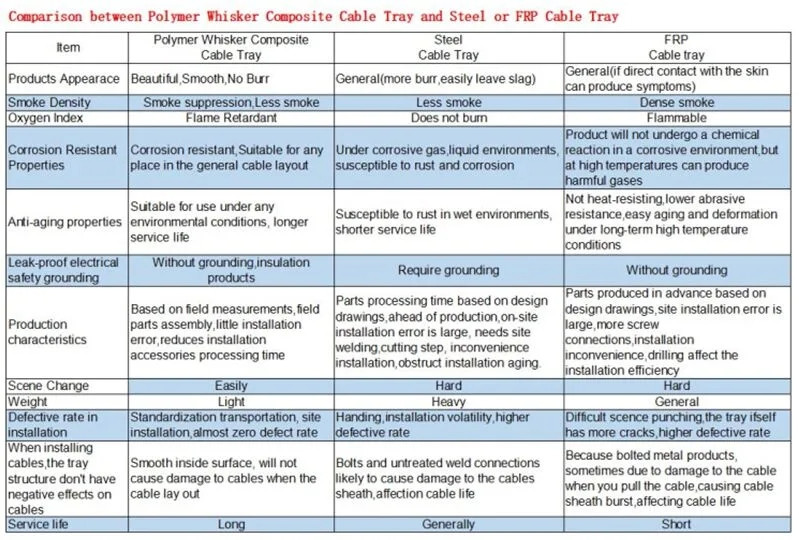

Overview of PHQ- high strength whisker modified plastic cable tray

It was produced according to American UL568 standard processing, and passed the National Fire Protection Building Materials Quality Supervision and Inspection and China Quality Certification Center CQC safety test. The product has advantage of insulation, corrosion-resistant, anti-aging, light weight and long service life. The company can produce according to customized demand for a variety of special products and recyclable recycling. The products have properties of environment protection, energy-saving and convenient to use. The products are widely used in the United States, France and Southeast Asian countries. It is the first new kind in our country, is a model of a new generation of scientific and technological innovation.

Macromolecule alloy cable tray is a new paragon of replacing steel with plastics after PVC fire-resistant cable trough in Electrical application engineer field. It has good physical properties and chemical properties, also possess the good features of PVC like fire-resistant, acid-resistant, alkali-resistant. Based on UL568 standard, it is made from a special high molecular material and mixed with functional additives containing other features. It's widely used in Europe and America, and developed countries and regions in Southeast Asia for its energy conservation and environment protection nature.

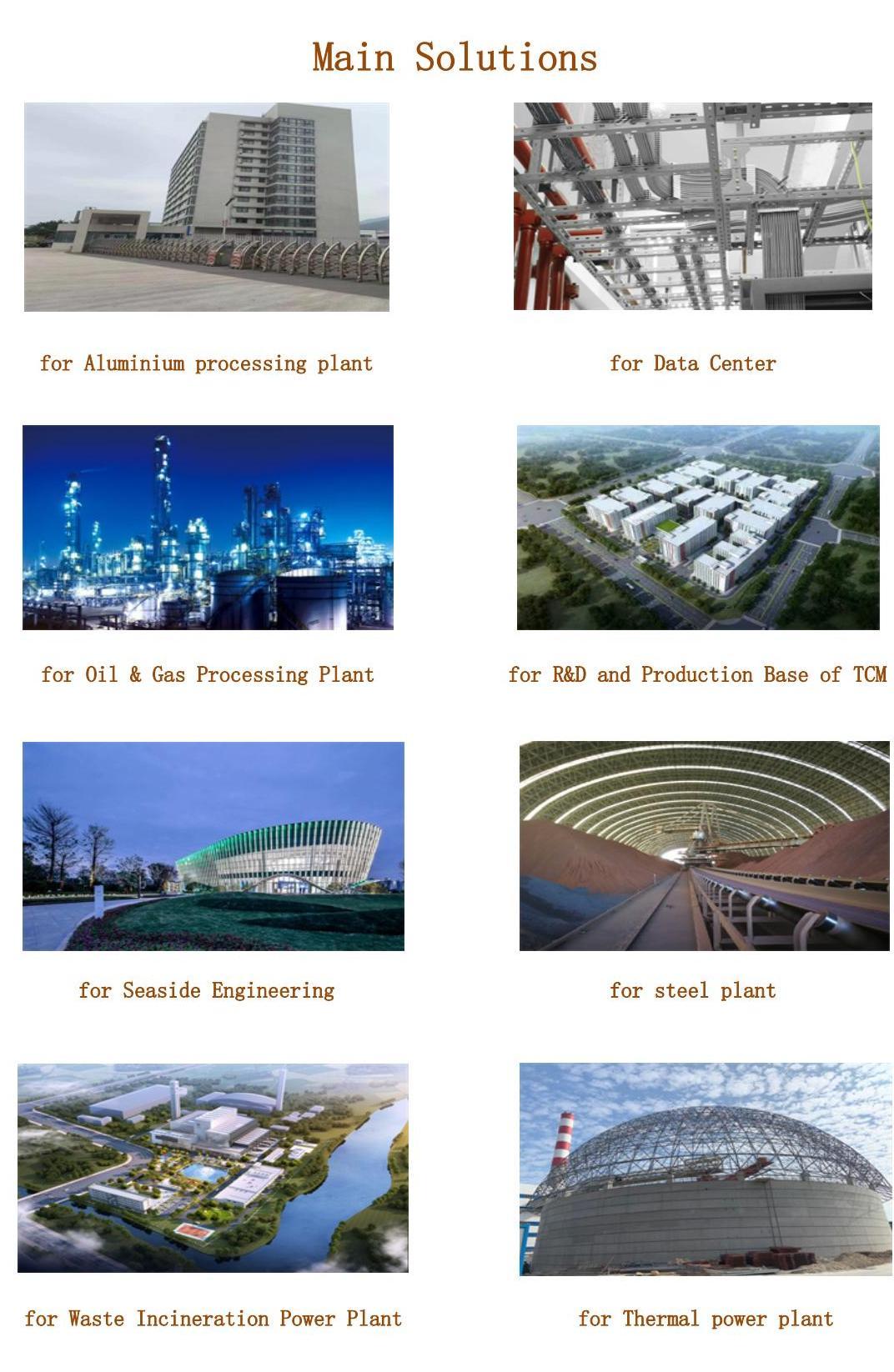

For its outstanding features and low cost, macromolecule alloy cable tray is approved and applied in different fields and industry. In developed countries and regions, it commonly used in the field of subway, mining, metallurgy, communication, oil, chemical engineering, coal, textiles, electricity, mechanical, transportation, shipping, water treatment, paper-making, civil building, industrial workshop, new energy PV and wind power project, etc.

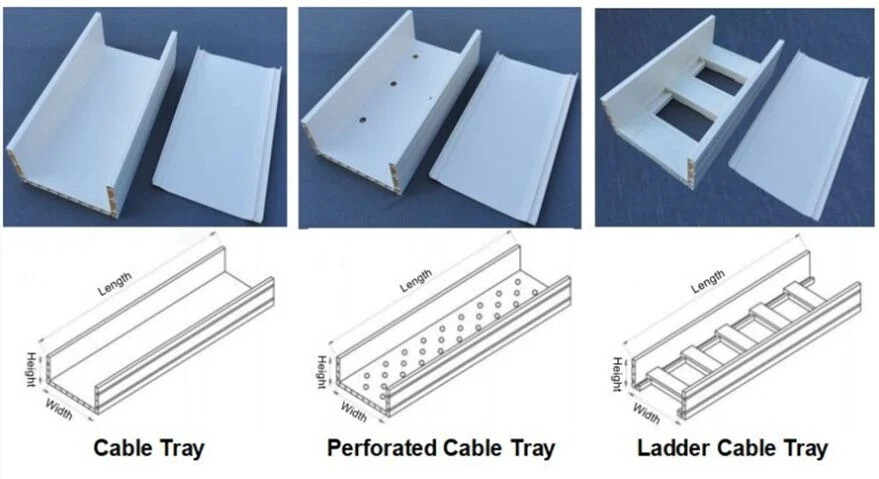

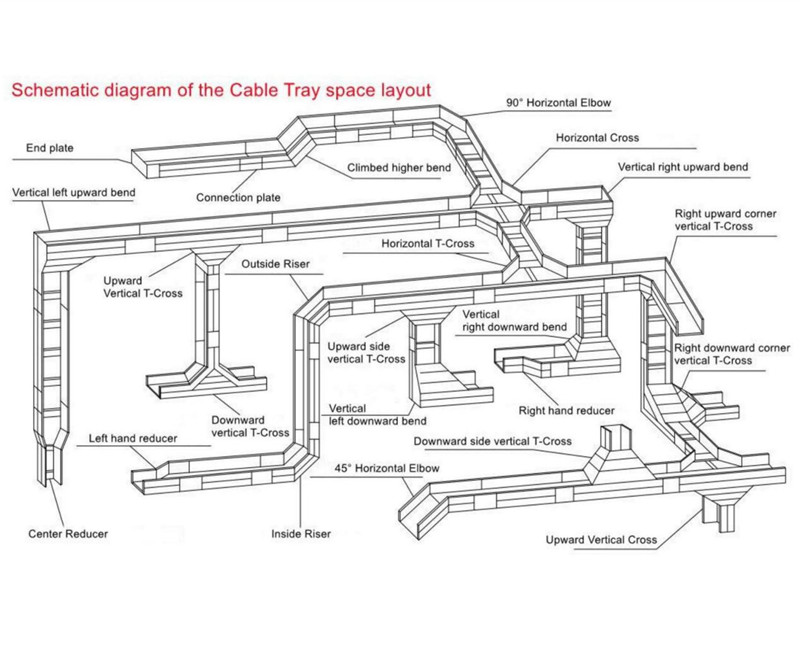

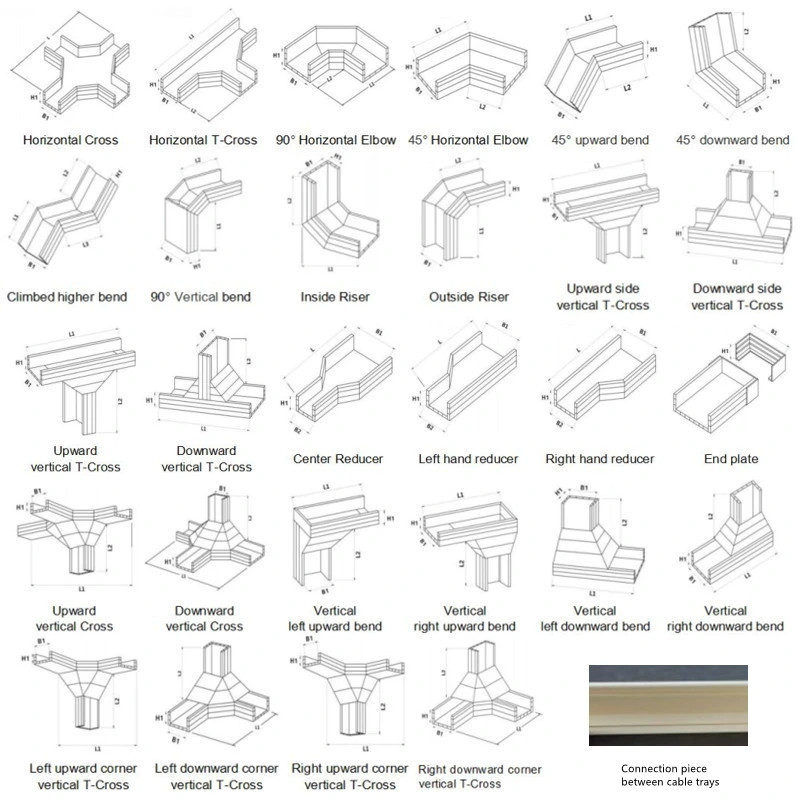

The channel-type of Macromolecule alloy cable tray is fully closed model. It is suit for lay of computer, telecommunication cable, power cable etc. and specially suit for protecting cables in heavy corrosion environment. Ladder type and tray type cable tray is made based on improved foreign-related technology, it has light weight, heavy duty, unique shape and other characteristics.

Macromolecule alloy cable tray is designed to suit different application scenario, which is accord with the advocated policy of Replacing steel with plastics, Energy-saving and cost-reducing, Environmental protecting. Under innovative and advanced design concept, Macromolecule alloy cable tray will be the priority choice in constructional engineering in near feature and have bright market prospect.

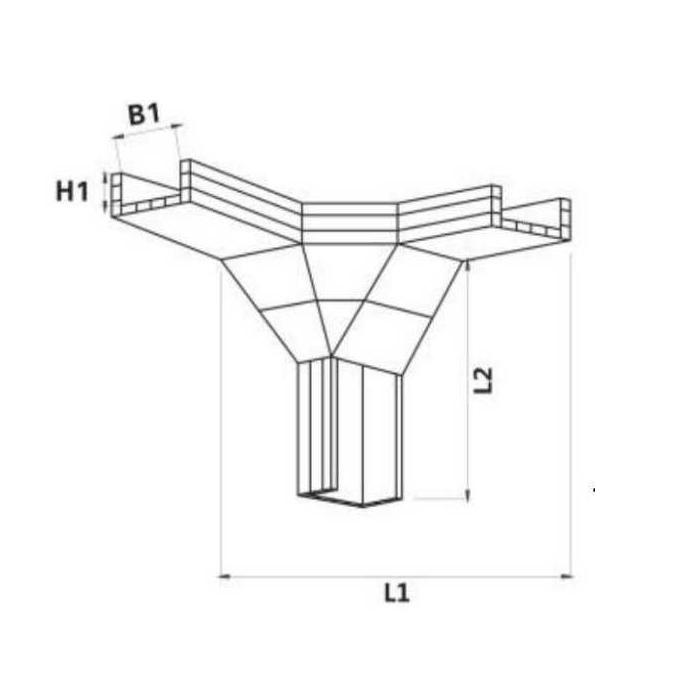

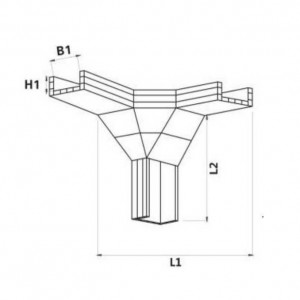

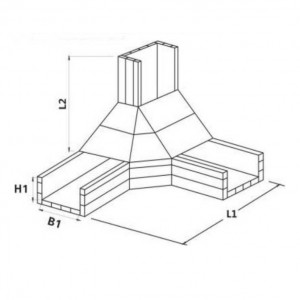

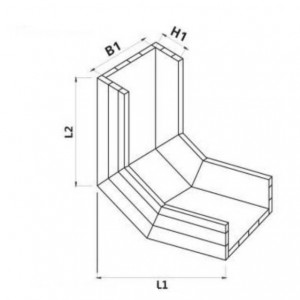

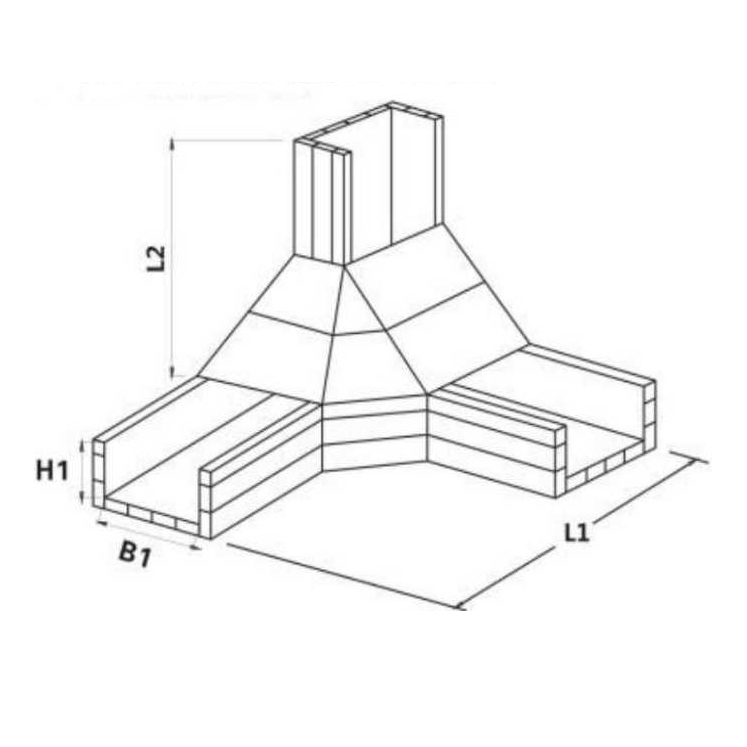

| Ordering Code | Specification | Center Line | ||

| B1 | H1 | L1 | L2 | |

| PHQ-C-3D

PHQ-K-3D PHQ-T-3D |

50 | 50 | 500 | 400 |

| 100 | 50/100 | |||

| 200 | 100

150 200 |

630 | ||

| 300 | 730 | |||

| 400 | 830 | |||

| 500 | 930 | 500 | ||

| 600 | 1030 | |||

| 800 | 1230 | |||

| 1000 | 1430 | |||

| 1200 | 1630 | |||

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

Q: Are you a factory or a trading company?

A:We not only have our own factories but also have shares in some other enterprises.

Q:What services you can offer?

A:We are manufacturer with a range of electrical and network cable tray systems , you can enjoy the one-stop shopping service from our company.Quality and cost driving manufacturer with ISO9001,CE,NEMA,UL,SGS certificated to provide customers reliable products with most competitive price.

Q:How can you make commitment passing the test?

A:We have professional lab to do below test:

a.safe loading test

b.galvanized thickness test

c.salt spray test

d.electrical continuity

Q:What is your products advantages:

A:

a.Reduce installation costs and time

b.Easy for changing, adding and moving

c.Bright surface means good material and quality

d.Our electrical and network cabling equipment have the same quality as the international famous brand.

Q: Can you provide samples?

A: Yes ,you can get the free samples.

Q: What is your payment terms?

A: 30% T/T deposit,balance will be paid before shipment or against the copy of B/L;

Q: How about the delivery time?

A: According to your order list and quantity,Normally delivery in 15-25days.

Q: Why do choose us?

A:

Cable Tray Official Certificates Worldwide

We has been certified by ISO9001 in China, UL in U.S.A and CE in E.U. with professional design and extremely well production techniques. These certifications are our first step into the International market.

Cable Tray Production Flow Strictly Managed

Our Factory has various types of CNC machines, high quality modeling machines, processing equipment, which provides the most powerful guarantee for high quality products.

Cable Tray Quality Traceability System Maintained

In order to serve high quality products, it is essential to test the manufactured products before delivery. In this session, Our factory develops the most stringent testing procedures, and trains factory inspectors besides its already high level product inspection equipment.

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |