Polymer Alloy plastic (PVC )HPVLBE Hesheng with the chemical structure of whisker modified

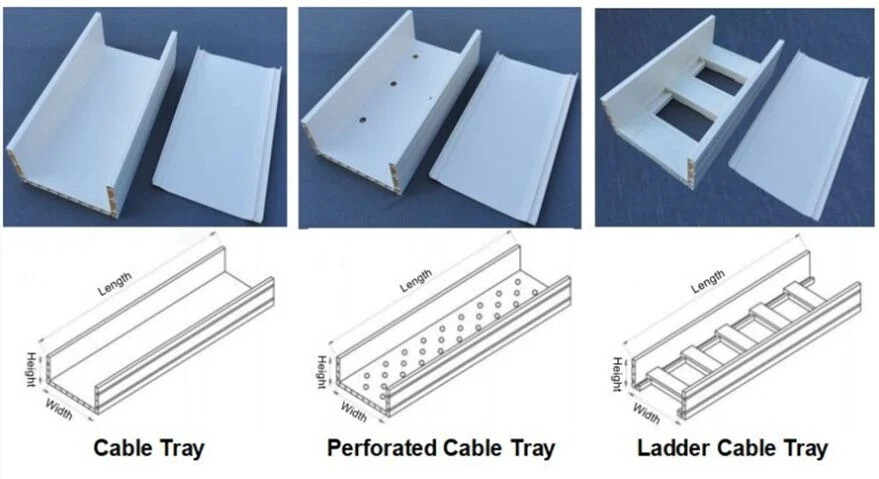

Overview of PHQ- high strength whisker modified plastic cable tray

Performance indexes of new polymer alloy plastic cable tray:

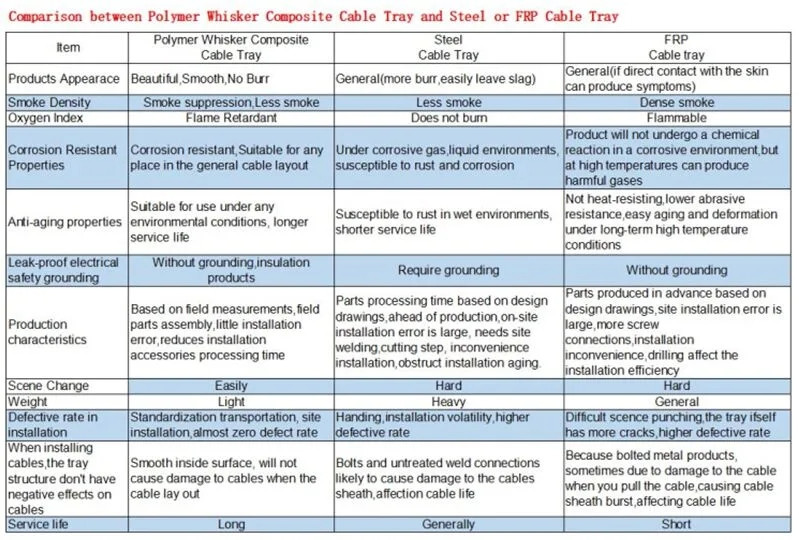

1.High strength:the new polymer alloy plastic cable bridge is made of a variety of different kinds of polymers,using the method of physical blending and chemical grease grafting,through the preparation process innovation,the product has two characteristics of steel toughness.

2 corrosion resistance:the new polymer alloy plastic cable tray bridge use special formula,this material overcomes the original steel bridge is easy to rust,easy to corrosion shortcomings,it is suitable for different climate environment and chemical corrosion environment.

3.Light weight:the proportion of the new polymer alloy plastic cable bridge is one third of that of the traditional steel bridge,which has great advantages in transportation and loading and unloading compared with the traditional steel bridge.

4.Non-conductive:the new polymer alloy plastic cable bridge has reliable insulation performance,surface resistivity is greater than 108 ohm,the product does not need to be grounded,and the traditional steel bridge,there should be reliable electrical connection and grounding,in order to protect the continuity of the circuit.

5.Strong flame retardant:the new type of polymer alloy plastic cable bridge is made of formula technology innovation,each index is in line with the requirements of non-combustible materials,combustion performance reaches GB 8624 B1 level,the product from the fire 1 second automatically extinguished.

6.Beautiful appearance:the new type of polymer alloy plastic cable bridge adopts the card groove connection,beautiful appearance.The steel bridge needs to weld and lock a large number of screws to complete the connection,and there will be slag inclusion,burn out,arc pit and other defects in welding.

7.Long life:the new polymer alloy plastic cable bridge adopts a unique formula,the product has the characteristics of strong weather resistance,in the general climate environment and chemical corrosion environment,its service life can reach more than 50 years.

8.Easy installation:the new type of polymer alloy plastic cable bridge adopts a double card groove connection,and the two sides of the side beam are equipped with 4 external bayonets, which not only increases the connection strength,but also has a beautiful appearance.It really achieves the effect of fast connection,safety and beauty.

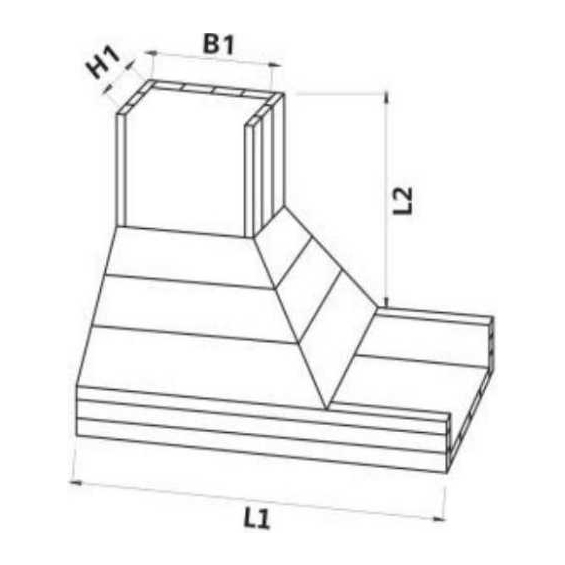

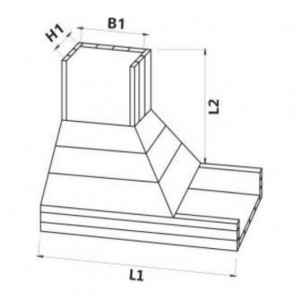

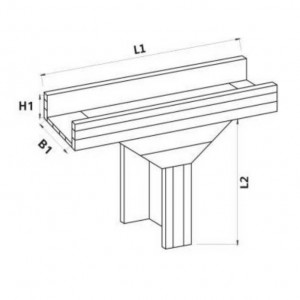

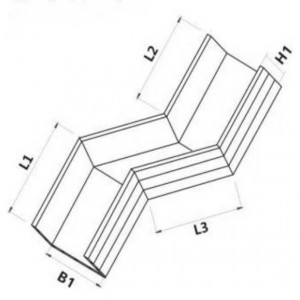

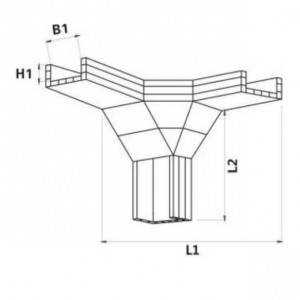

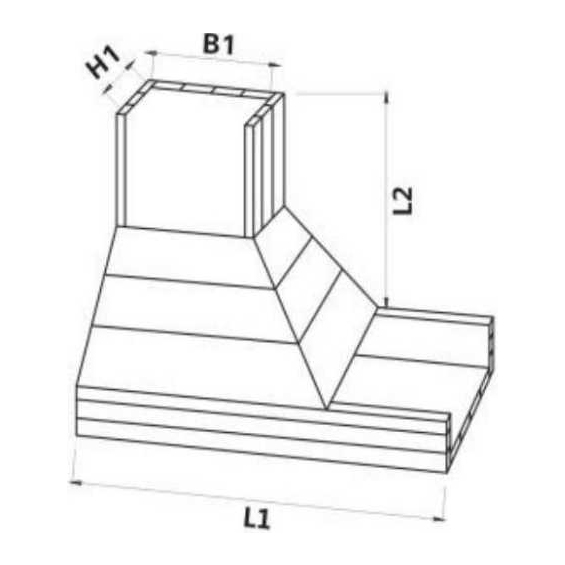

| Ordering Code | Specification | Center Line | ||

| B1 | H1 | L1 | L2 | |

| PHQ-C-2I

PHQ-K-2I PHQ-T-2I |

50 | 50 | 470 | 400

500 |

| 100 | 50/100 | |||

| 200 | 100

150 200 |

630 | ||

| 300 | 730 | |||

| 400 | 830 | |||

| 500 | 930 | |||

| 600 | 1030 | |||

| 800 | 1230 | |||

| 1000 | 1430 | |||

| 1200 | 1630 | |||

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

Q: Are you a factory or a trading company?

A:We not only have our own factories but also have shares in some other enterprises.

Q:What services you can offer?

A:We are manufacturer with a range of electrical and network cable tray systems , you can enjoy the one-stop shopping service from our company.Quality and cost driving manufacturer with ISO9001,CE,NEMA,UL,SGS certificated to provide customers reliable products with most competitive price.

Q:How can you make commitment passing the test?

A:We have professional lab to do below test:

a.safe loading test

b.galvanized thickness test

c.salt spray test

d.electrical continuity

Q:What is your products advantages:

A:

a.Reduce installation costs and time

b.Easy for changing, adding and moving

c.Bright surface means good material and quality

d.Our electrical and network cabling equipment have the same quality as the international famous brand.

Q: Can you provide samples?

A: Yes ,you can get the free samples.

Q: What is your payment terms?

A: 30% T/T deposit,balance will be paid before shipment or against the copy of B/L;

Q: How about the delivery time?

A: According to your order list and quantity,Normally delivery in 15-25days.

Q: Why do choose us?

A:

Cable Tray Official Certificates Worldwide

We has been certified by ISO9001 in China, UL in U.S.A and CE in E.U. with professional design and extremely well production techniques. These certifications are our first step into the International market.

Cable Tray Production Flow Strictly Managed

Our Factory has various types of CNC machines, high quality modeling machines, processing equipment, which provides the most powerful guarantee for high quality products.

Cable Tray Quality Traceability System Maintained

In order to serve high quality products, it is essential to test the manufactured products before delivery. In this session, Our factory develops the most stringent testing procedures, and trains factory inspectors besides its already high level product inspection equipment.

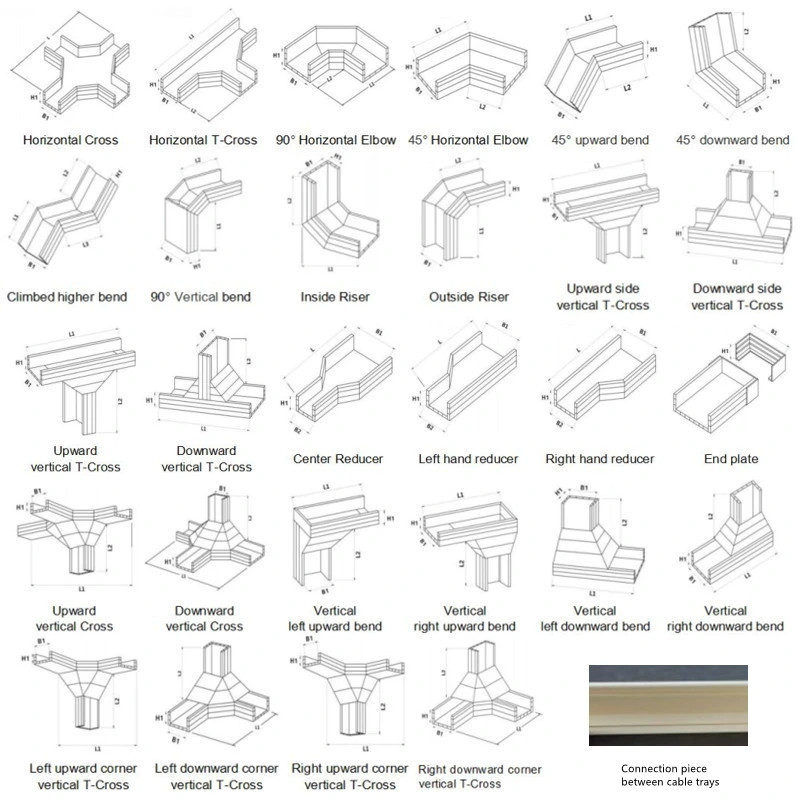

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |