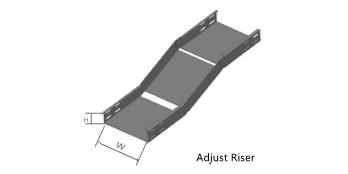

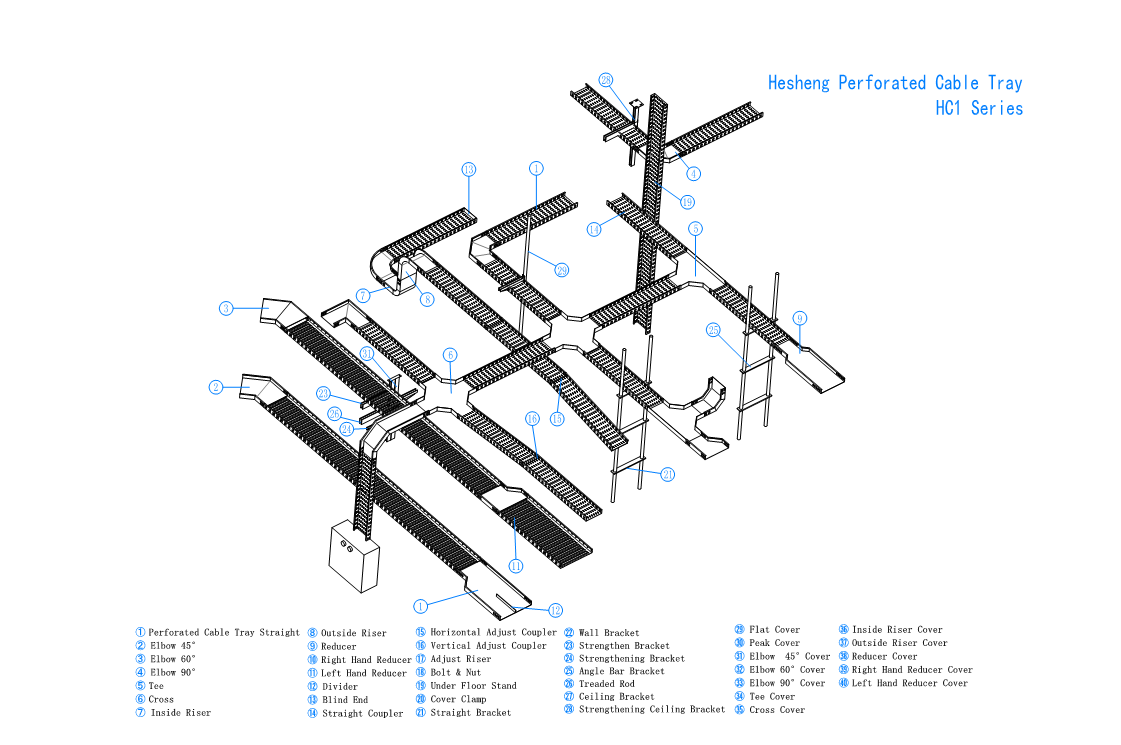

HC1-AR Hesheng Perforated Adjust Riser

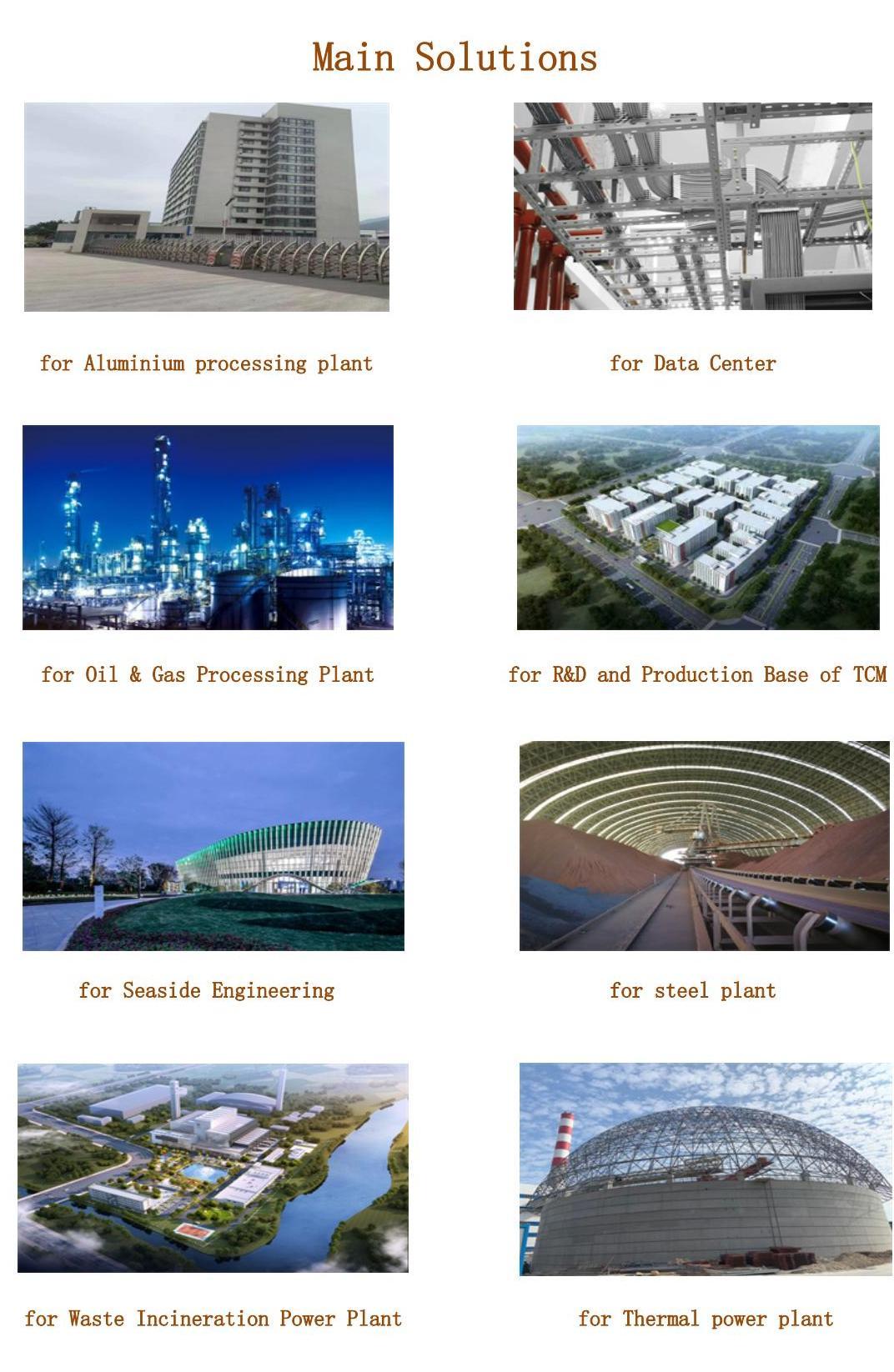

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

Channel Cable Trays consist of a one-piece, ventilated or solid bottom contained within longitudinal side members. Provides ventilation with added cable support frequency and with the bottom configuration providing cable support every 4 or less inches. Available in metal and nonmetallic materials. Generally used with control and instrumentation cables in moderate heat generating applications with short to intermediate support spans of 5 feet to 20 feet. Trough cable tray bottom is available in flat sheet or corrugation that is 3 times stronger and 21 times stiffer than flat sheet bottoms. Corrugated seams between jointing sections eliminate the need for bottom seam splices. Load Depths: 3" through 9".Channel Cable Tray is available in the following material types: mill steel, carbon steel, pre-galvanized steel, steel HDG, and stainless steel, aluminum, polymer alloy, plastic, FRP or GRP.

Moreover,H.S. also develop various accessories for our range which are used for support & installation of cables over the cable trays.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

|

Odering Code |

W |

H |

|

|

HC1-AR |

HC1-AR-50-50 |

50 |

50 |

|

HC1-AR-100-50 |

100 |

50 |

|

|

HC1-AR-150-50 |

150 |

50 |

|

|

HC1-AR-200-50 |

200 |

50 |

|

|

HC1-AR-250-50 |

250 |

50 |

|

|

HC1-AR-300-50 |

300 |

50 |

|

|

HC1-AR-450-50 |

450 |

50 |

|

|

HC1-AR-600-50 |

600 |

50 |

|

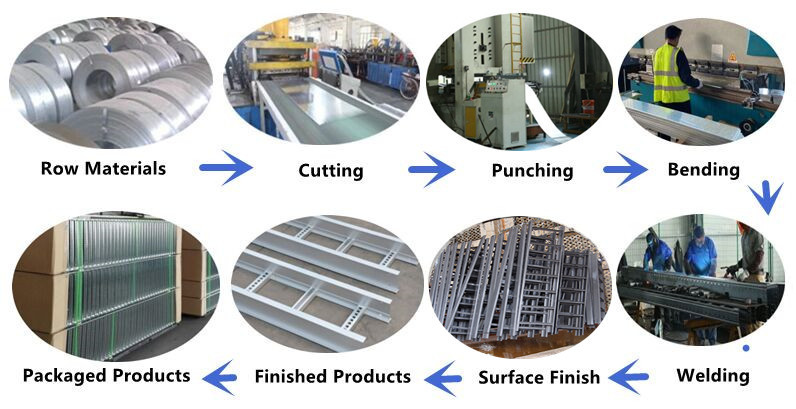

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

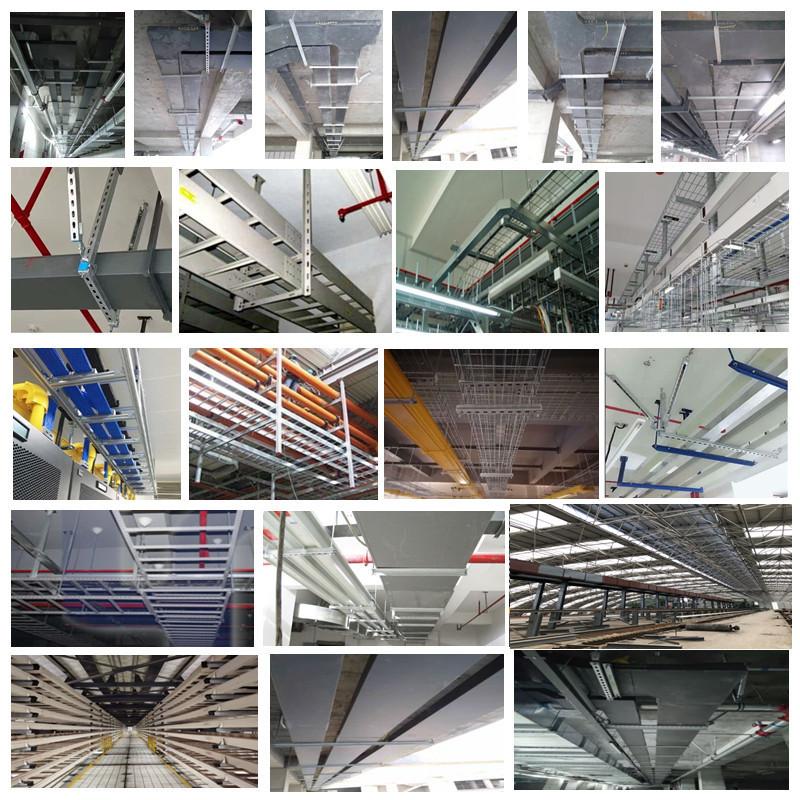

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |