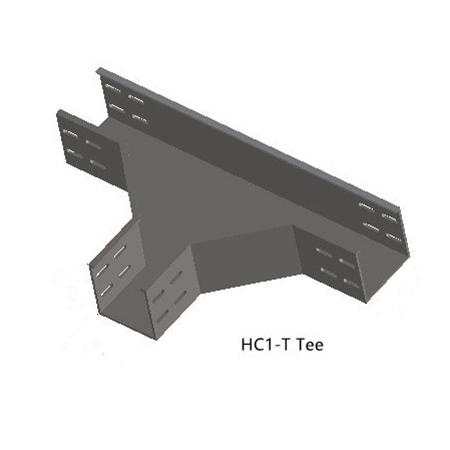

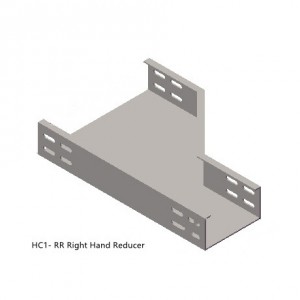

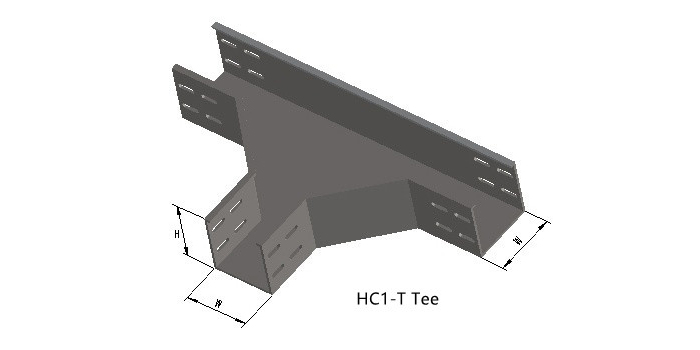

HC1-T Hesheng Perforated Tee-Cross

HC1-T Tee of Hesheng Perforated Cable Tray

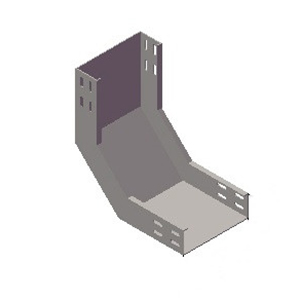

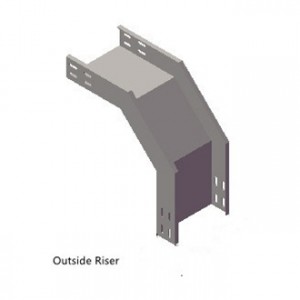

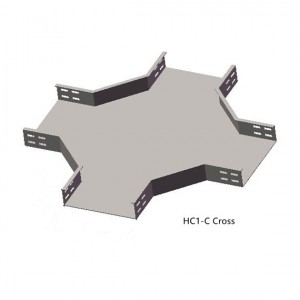

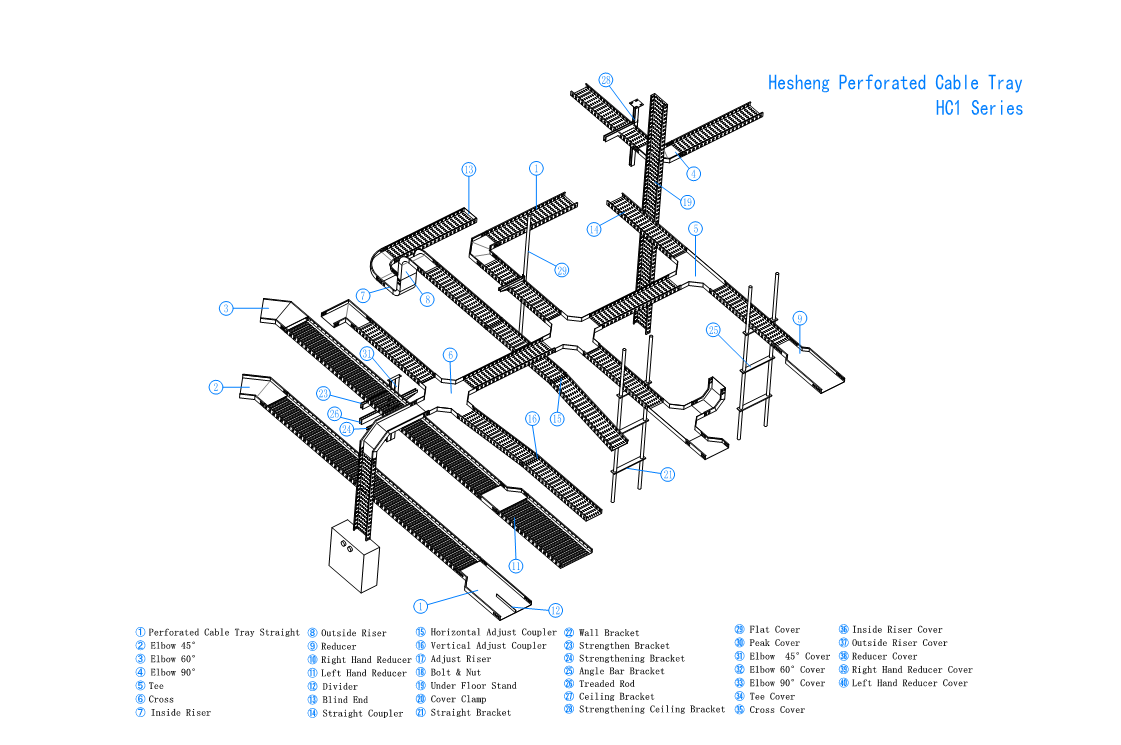

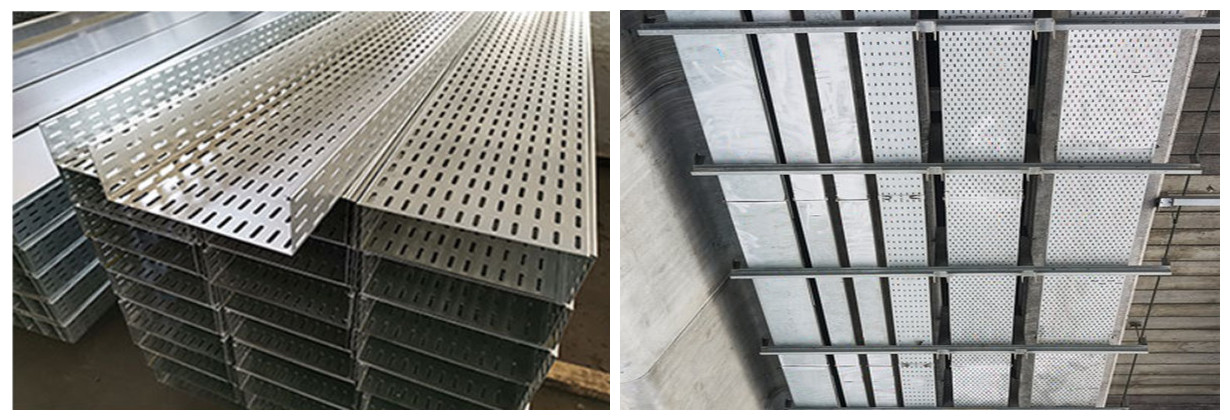

H.S.offer a wide range of compents of perforated cable trays. T-Cross is one of the components used as a 3-way cross.Cable tray fittings are used to change the size or direction of the channel tray. The most important decision to be made in fitting design concerns radius. The radius of the bend, whether horizontal or vertical, can be zero (non-radius), 12 in., 24 in. or greater on a custom basis. The selection requires a compromise with the considerations being available space, minimum bending radius of cables, ease of cable pulling and cost. The typical radius is 24 inches. Fittings are also available for 30°, 45°, 60° and 90° angles. When a standard angle will not work, adjustable elbows can be used. It may be necessary to add supports to the tray at these points.

T-cross is one of the components used in the right-angle corner.

Moreover,H.S. also develops various accessories for our range which are used for suppot & installation of cables over the cable trays.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Simple Usage

·Durability

|

Oerdering Code |

W(mm) |

H(mm) |

|

|

HC1-T |

HC1-T-50-50 |

50 |

50 |

|

HC1-T-100-50 |

100 |

50 |

|

|

HC1-T-150-50 |

150 |

50 |

|

|

HC1-T-200-50 |

200 |

50 |

|

|

HC1-T-250-50 |

250 |

50 |

|

|

HC1-T-300-50 |

300 |

50 |

|

|

HC1-T-400-50 |

400 |

50 |

|

|

HC1-T-450-50 |

450 |

50 |

|

|

HC1-T-500-50 |

500 |

50 |

|

|

HC1-T-600-50 |

600 |

50 |

|

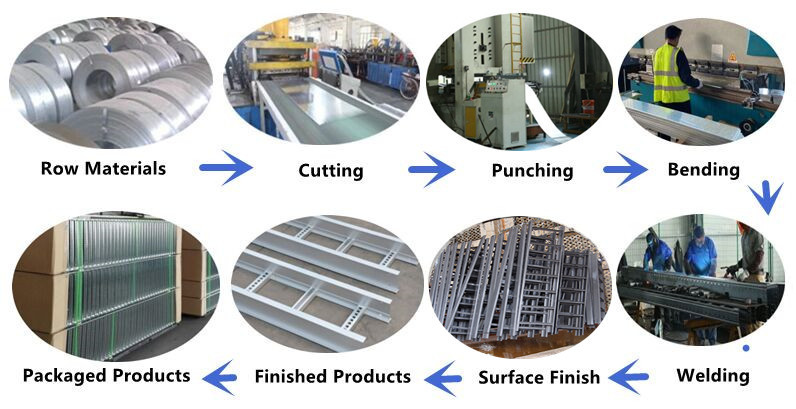

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

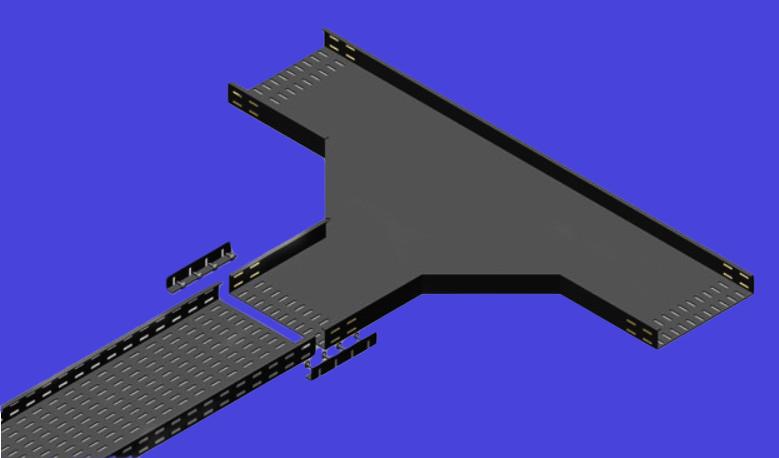

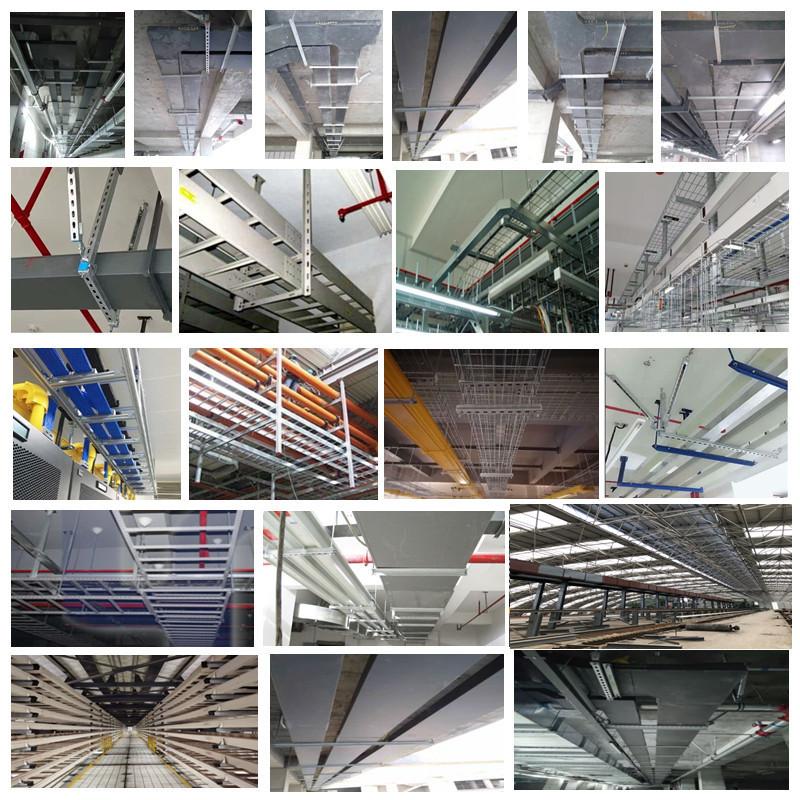

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |