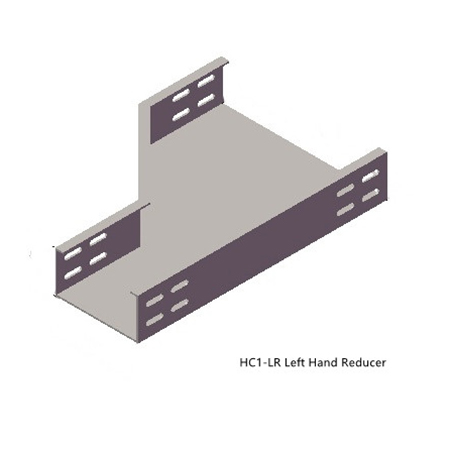

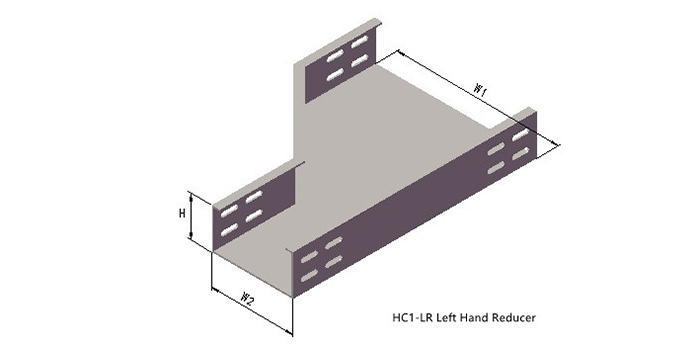

HC1-LR Left Hand Reducer

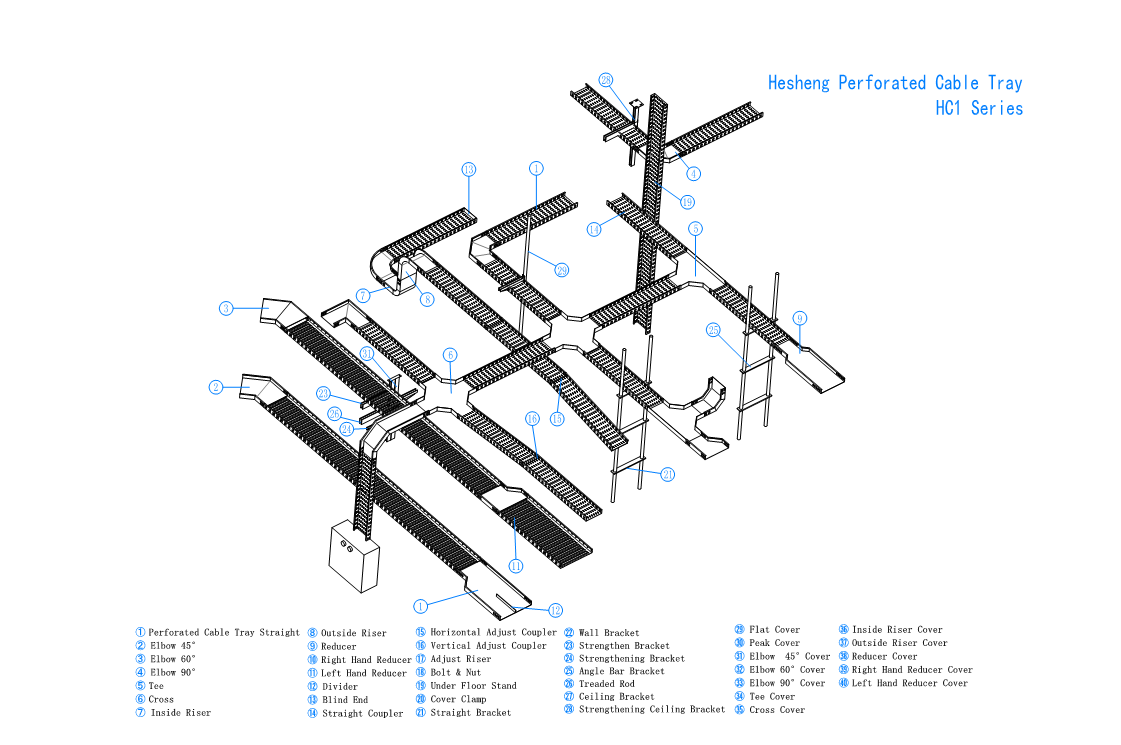

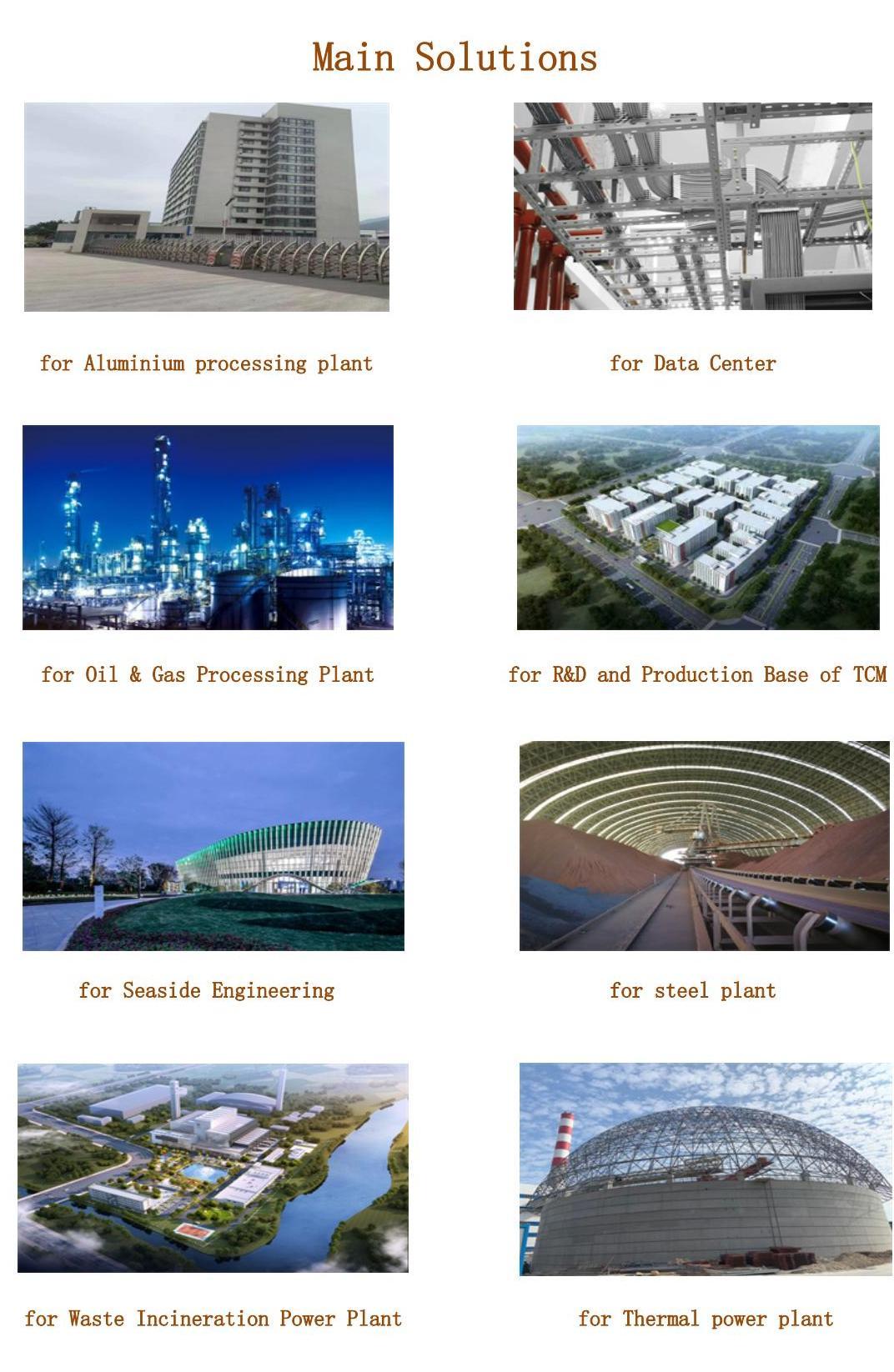

Hesheng solid and perforated bottom cable tray system is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder.

perforated cable tray allows for hold down or cable attachment, and heat dissipation.

Cable trays are UL-classified as an equipment grounding conductor, so they require no ground straps. They are available in aluminum, steel, fiberglass, or stainless steel and come with a finish (primarily for indoor applications) or galvanized.

Cable-tray bottom configurations include ladder-type, which is suitable for most needs. But consider flat-bottom trays if you plan to fill them to capacity or if you plan to use high-performance cabling because such cabling requires low stress on cables.

The NEC does not have a specific installation clearance, but indicates in section 318-6(b) that cable trays should be exposed and accessible. Telecommunications standard TIA/EIA-569 recommends a minimum of 12-inch access headroom above the cable tray.

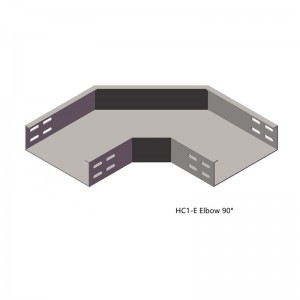

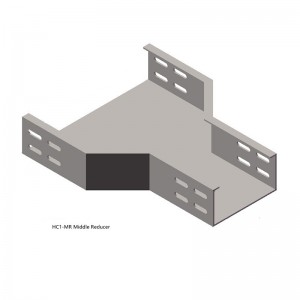

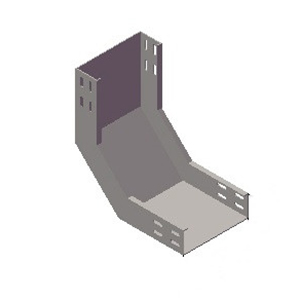

Moreover,H.S. also develop various accessories for our range which are used for support & installation of cables over the cable trays.

H.S.offers a wide range of components of perforated cable trays.Left Hand Reducer is one of the components,used as reducer connector at left side.

These perforated cable trays are offered in different materials , generally fabricated in mild steel, Pre-galvanized, Hot-dip Galvanized,Stainless Steel,Aluminium,Fiber Reinforced Plastic, Plain Steel with powder coated,Polymer Alloy Cable supporting System.

The accessories are mentioned below:

·Fitings

·Clamps

·Supports

Advantages:

·Corrosion Resistance

·Easy-installing

·Durability

|

Odering Code |

W1(mm) |

W2(mm) |

H(mm) |

|

|

HC1-LR |

HC1-LR-100-50 |

100 |

50 |

50 |

|

HC1-LR-150-50 |

150 |

50 |

50 |

|

|

HC1-LR-200-50 |

200 |

50 |

50 |

|

|

HC1-LR-150-100 |

150 |

100 |

50 |

|

|

HC1-LR-200-100 |

200 |

100 |

50 |

|

|

HC1-LR-250-100 |

250 |

100 |

50 |

|

|

HC1-LR-200-150 |

200 |

150 |

50 |

|

|

HC1-LR-300-150 |

300 |

150 |

50 |

|

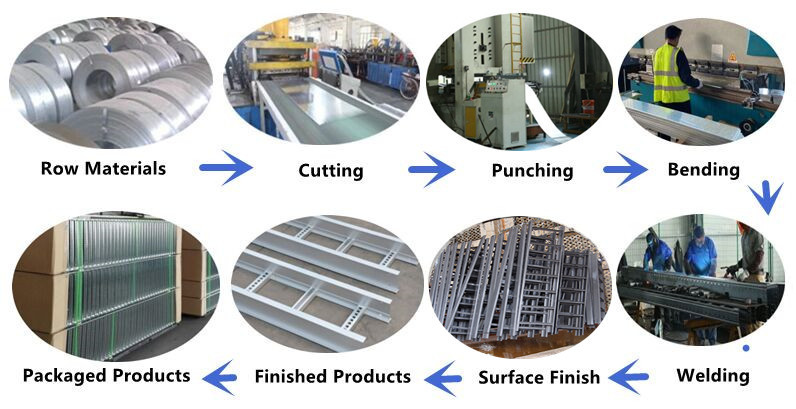

Production line for Metal Cable Tray Here is processing line of cable tray and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

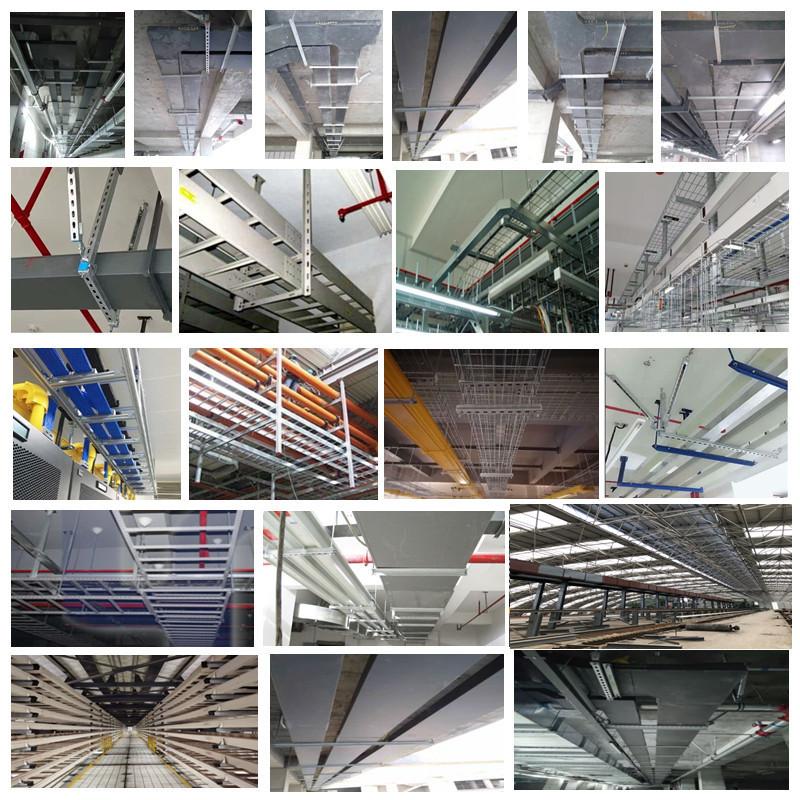

Installation cases on site for cable tray with holes, metal cable ladder,metal cable trunking,wire mesh cable tray,wireway, cable channel,solid bottom cabletray, polymer alloy cable tray,which can be applied in the

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |