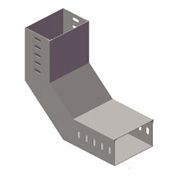

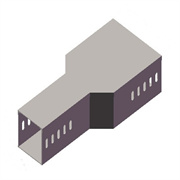

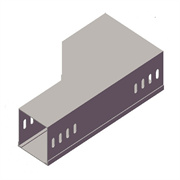

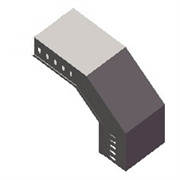

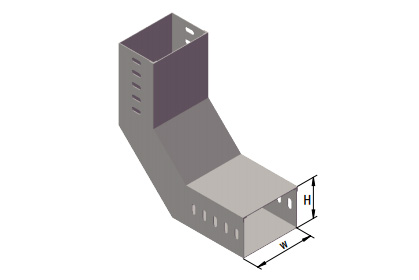

HT1-IR Hesheng Metal Inside Riser for Cable Trunking

Hesheng HT1- IR Inside Riser

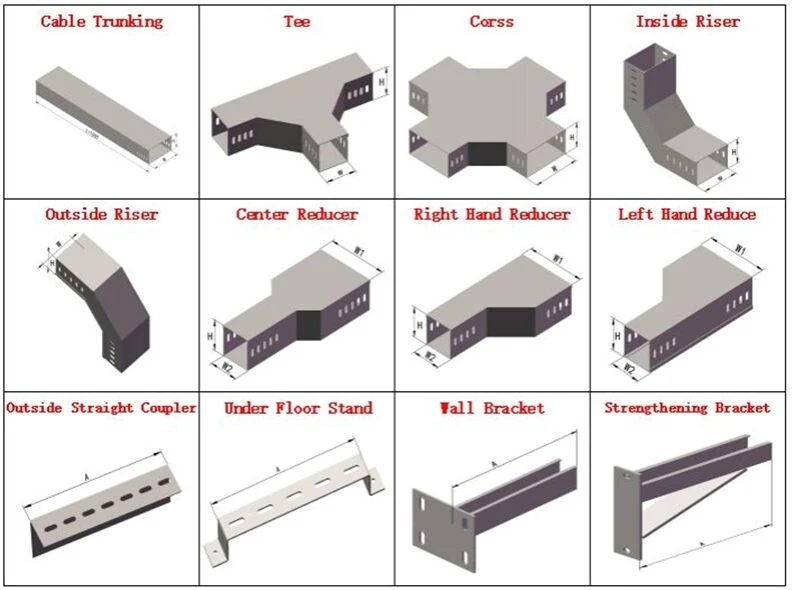

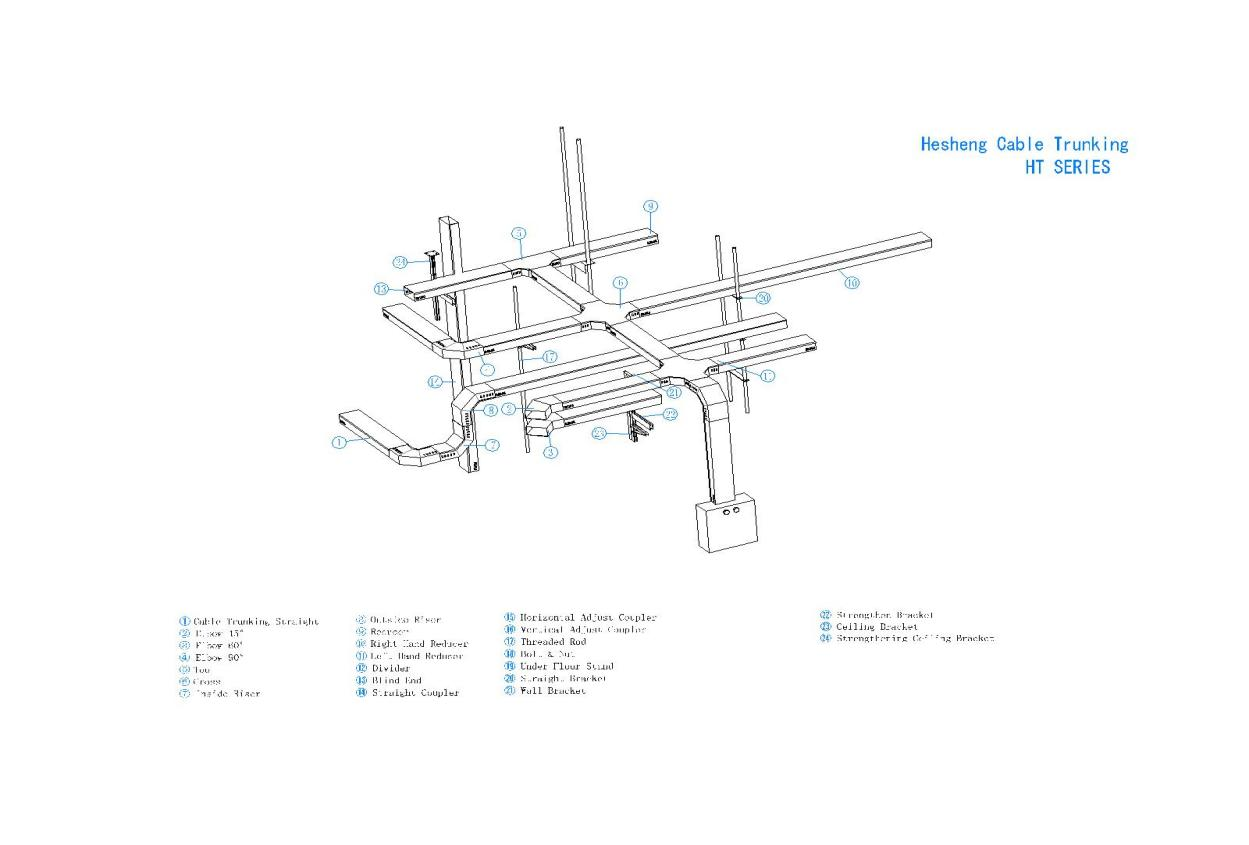

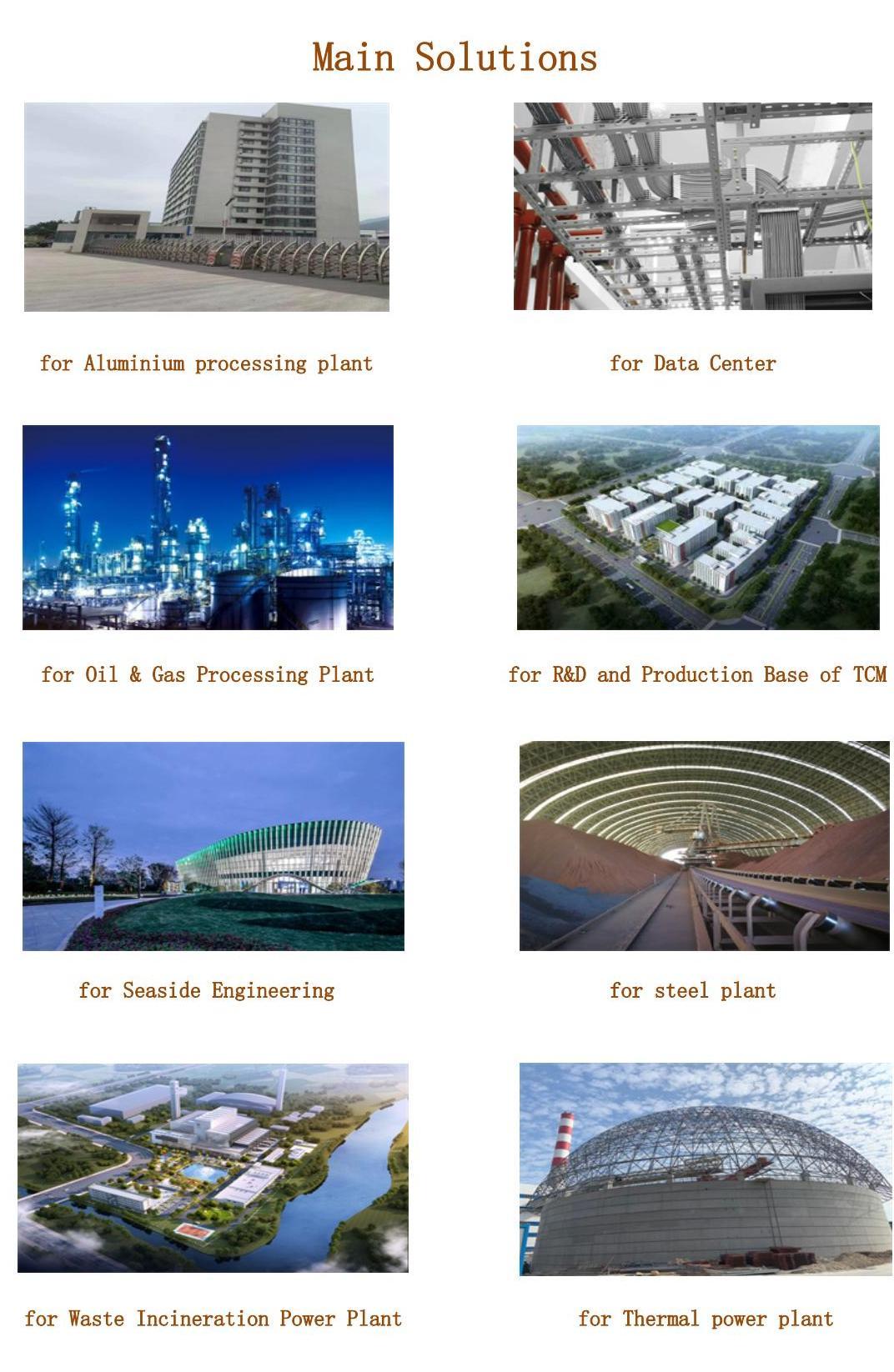

Hesheng CableTrunking HT1 is ideal solution for instrumentation cable and electrical cable runs in industrial or commercial cable management applications, helping eliminate the need for conduit or ladder, used for cable and wire junction, distribution and termination.HT1- IR Inside Riser is one of the components,used as vertical downward bend.

What is the Difference between Electrical Conduit and Trunking?

Electric conduit is a tube made of metal or plastic that protects and routes the electrical wiring of a structure or building. It helps to protect the electric wiring from moisture and mechanical impact. Another benefit of the electric conduit is it ensures safety since it will be easy to withdraw the conductors that are currently there are replace them with new ones. Electric conduit is also essential since it is reliable, durable.

On the other hand, the electrical trunking system consists of a rigid piece of PVC, copper or aluminum and is used where different electrical cables come together since it helps to carry a compound current. Electrical trunking system ensures safety from dust and humidity. It also prevents damage of the cable insulation and is long lasting. Examples of the trunking options include the small fiberglass cable and PVC coated.

When to Use Trunking or Conduit?

Conduit system is ideal for installations in external and damp environments. It protects the conductors from harmful substances, including moisture and chemicals. Moreover, it is the best wiring systems for buildings that will undergo changes in the future since it can be altered and removed easily. It can be submerged in water. Installation companies can also use metal conduit systems to minimize electromagnetic interference.

Trunking system is ideal for the distribution of high currents in buildings, equipment, and switching yards. This installation type distributes current when multiple electrical cables are used.

Standard finish of H.S. Cable Trunking as below,customize available:

·G---- Pre-galvanized steel

· H---. Hot Dip Galvanized

·S4 -- Stainless Steel SS304

· S6-- Stainless Steel SS316

· A---. Aluminium

·FRP- Fiberglass Reinforced Plastics / GRP H,S

Cable Trunking Advantages:

· Cheap and easy installation method.

· The cables are enclosed in trunking, there is no risk of cable insulation to be damaged.

· Cables are safe against dust and humidity.

· Alternations are possible.

· Long Service Life.

Disadvantages:

· Expensive compare to other wiring systems.

· Care and good workmanship are needed to ensure a successful installation.

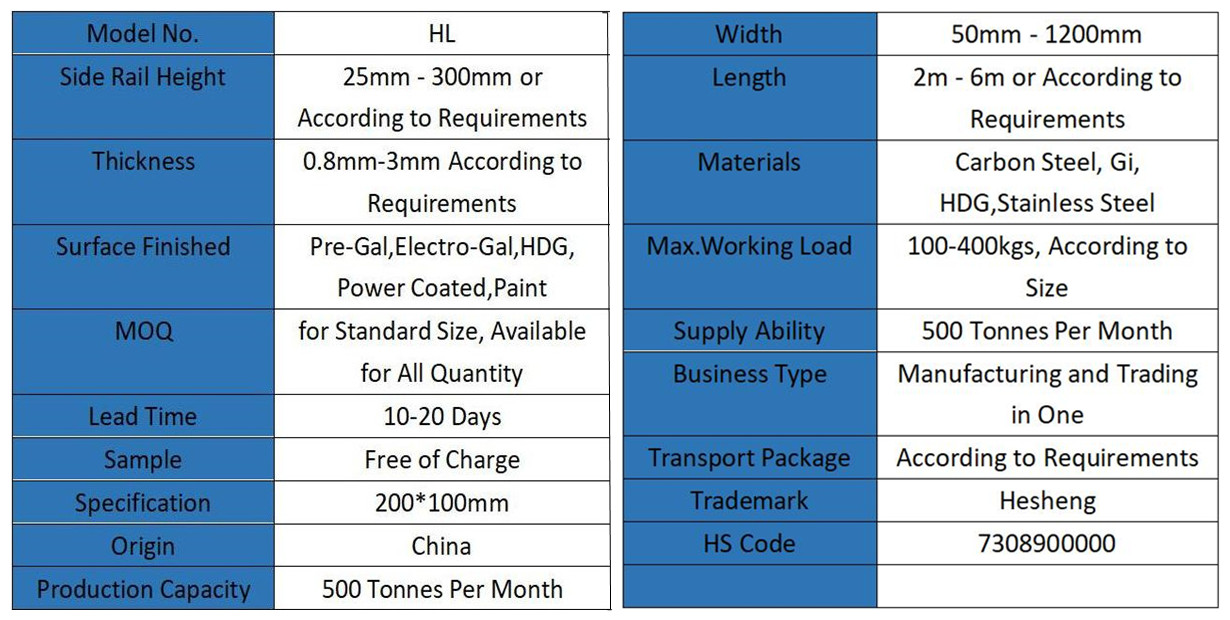

|

Ordering Code |

W(mm) |

H(mm) |

|

|

HT1-IR |

HT1-IR-100-100 |

100 |

100 |

|

HT1-IR-150-100 |

150 |

100 |

|

|

HT1-IR-200-100 |

200 |

100 |

|

|

HT1-IR-300-100 |

300 |

100 |

|

|

HT1-IR-400-100 |

400 |

100 |

|

|

HT1-IR-450-100 |

450 |

100 |

|

|

HT1-IR-500-100 |

500 |

100 |

|

|

HT1-IR-600-100 |

600 |

100 |

|

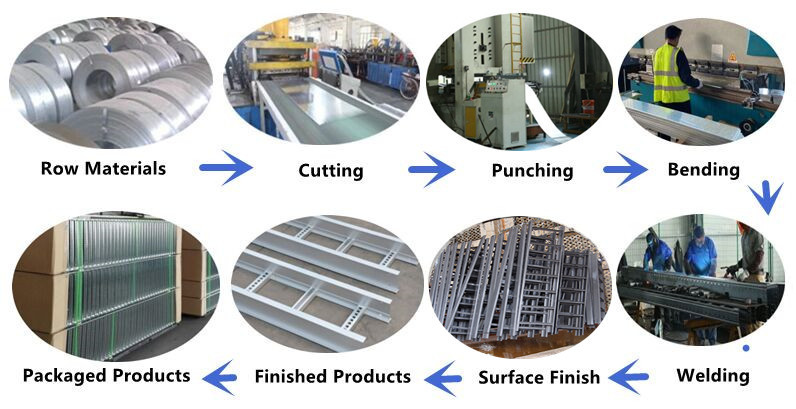

Production line for Metal Cable Tray Here is processing line of cable support system and welcome to visit our plant

Packing Method:

1.In bundle

2.Wrapping Film,plastic tape, Plywood pallet.

3.Plywood Pallets is optional for wire basket cable tray

4.Carton for accessories

5.As per requirements

Standard finish of H.S.Perforated Cable Tray as below, customize available:

| Suffix | Finish | Suffix | Finish | Suffix | Finish |

| G | Pre -galvanized/PG/GI | P | Powder coated | Z | Zinc plated |

| H | Hot dip galvanized/HDG | A | Alumnium | E | Electrolytic polishing |

| S4 | Stainless steel SS04 | FRP | Fiber reinforced plstic/GRP | M | Mill/Plain steel |

| S6 | Stainless steel SS06 | F | Fire rated |